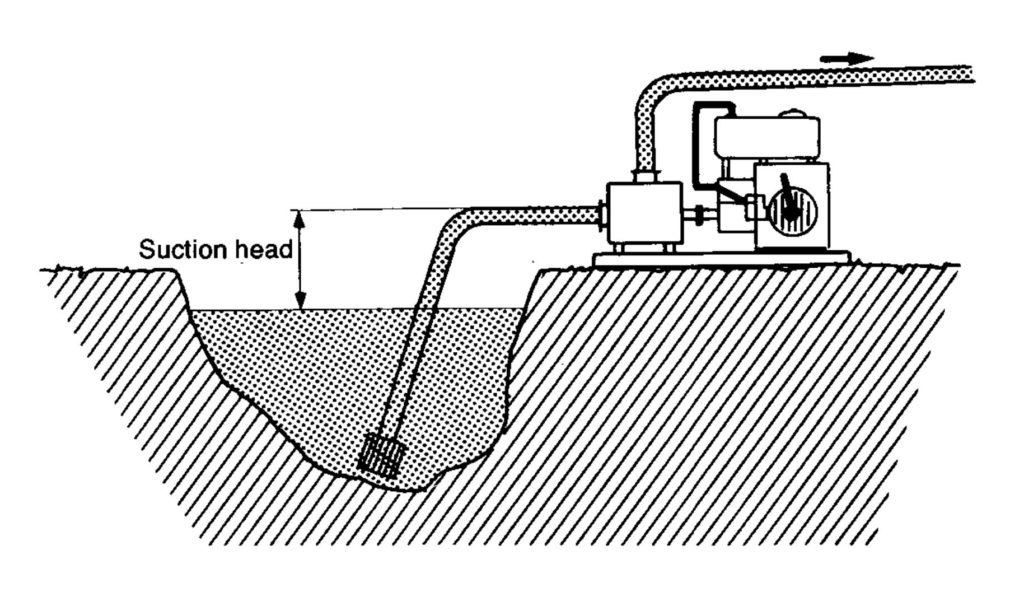

Combustion engine driven sump pump

Combustion engine driven sump pump are used where there is a need of pumping, e.g. drain a pit, well or similar, where there’s no current pump installed or where there is no electrical power easily assessable.

Pumping Unit

Self-priming sump pump with a petrol or diesel engine. Suction hose with strainer. Discharge hose is normally about 10 m long. Jointing permissibie when necessary. Sometimes equipped with transport carriage for heavy apparatus.

Size of pumps

Excavated pits 2-5 meter square filled with rain water or groundwater require 2 in. pumps with motor approx. 4 kW (5.5 hp.). Water flow about 500 liter/min 30 m3/h. Weight of pump about 25 kg.

For greater water flow use 3 in. pumps with motors approx. 6 kW (8 hp.). Larger pumps can also deal with larger particles. The mesh of the suction strainer is adapted to the inner passages of the pump. In practice it is that all bodies capable of passing through the strainer are permissible for pumping.

In the case of a discharge hose which is more than about 30 meter long, it is advisable to check the pressure drop of the hose (easily calculated with the aid of the nomogram in pumpbook Chapter 8.12). This pressure drop has the effect of reducing the flow capacity of the pump.

Erection

Place the pump on a flat and if possible rigid base. The difference to the water level (suction head) should not exceed 5-6 m. The suction hose should ascend uninterruptedly to the pump. Position the suction strainer near the bottom without burying it in clay, etc. In the case of small flow the strainer is placed in a pump pit approx. 0.5 x 0.5 m.

Pumping

Fill the pump with water through the filler. The amount of water necessary is normally 2 to 5 litres but this depend on the volume that needs to be filled (total pump suction pipe volume and pump volute volume). Start up and evacuate the suction pipe. If the time for evacuation to start is longer than a few minutes, there is a fault, e.g. too great a suction head, leaky suction hose, worn-out pump, etc.

As the level in the pit reduces, move the strainer to greater depths. If there is a lot of water, it is only necessary to check the pump every quarter of an hour. A full fuel tank in a well dimensioned combustion engine sump pump usually suffices for 2-3 hours, but avoid running dry.

If the supply flow of water is slight, reduce the engine throttle adjustment to a suitable level and allow the pump to lap. When pumping is completed, remove the water from the pump casing (risk of freezing).

Before placing in storage, wash the pump in clean water to avoid blockage caused by dried out clay or hardened concrete.

State when purchasing:

- Desired rate of flow and corresponding value for delivery head.

- Suction head.

- Evacuation times for new pump and worn-out pump.

- Maximum size of particles.

- Desired power source, e.g. 4-stroke petrol engine.

- Dimensions and design of hose connections.

- Maximum weight.

- Maximum noise level.

- Requirements with respect to protective safety frame with handle, runners, transport carriage, etc.

Pitfalls

Leaky suction hose results in reduced pump performance. An air leak on the suction side be detected by placing the discharge hose under water. Air bubbles indicate air leakage in the suction hose or the pump.

Petrol-oil mixtures should only be used for two-stroke engines.

A blocked suction strainer reduces the capacity of the pump. In such cases make a coarser filter of available materials, e.g. chicken netting, spruce twigs, etc.

Folds in the discharge hose cause unnecessary throttling.

Responses