4.5 Materials resistant to cavitation

Materials resistant to cavitation

Materials resistant to cavitation might be the only solution solving a cavitation damaging problem. However, a pump with developed cavitation is also loosing in performance. Flow, pressure and efficiency will be lower than stated in the pump curves and changing to materials resistant to cavitation will not be a remedy for performance but only for extended life time of parts.

Cavitation occurs when the local pressure in a liquid falls under the liquids vapor pressure at that liquids temperature. When cavitation occurs inside a pump, vapour bubbles are formed. When pressure increase inside the pump the vapour bubbles implode, resulting in local pressure shocks of up to about 10 000 MPa (10 000 MN/m²). Implosions close to a boundary surface in a pump impose a hammering load on the surface with the result that fragments of material are loosened. Cavitation damage thus has a typical appearance, see figure 4.5a.

The surface becomes rough and spongy in appearance, and is limited to those zones in a pump where low pressure can occur.

Figure 4.5a Pump impeller exhibiting cavitation damage.

If cavitation damage has been caused in a pump, the first thing to do is to improve the NPSH of the installation by:

- increasing the available supply head or reducing the suction lift

- by elevate the tank or increase the level in the suction tank

- decrease losses in suction pipe by eliminating bends, valves and other restrictions

- decrease losses in suction pipe by enlarge suction pipe diameter, shorten suction pipe

- decrease flow if possible, it will reduce friction loss (increase pressure at pump suction) and increase NPSHr / NPSH3

- increase NPSHr by using an inducer impeller

- lowering the temperature of the liquid ahead of the pump intake either by direct or indirect cooling.

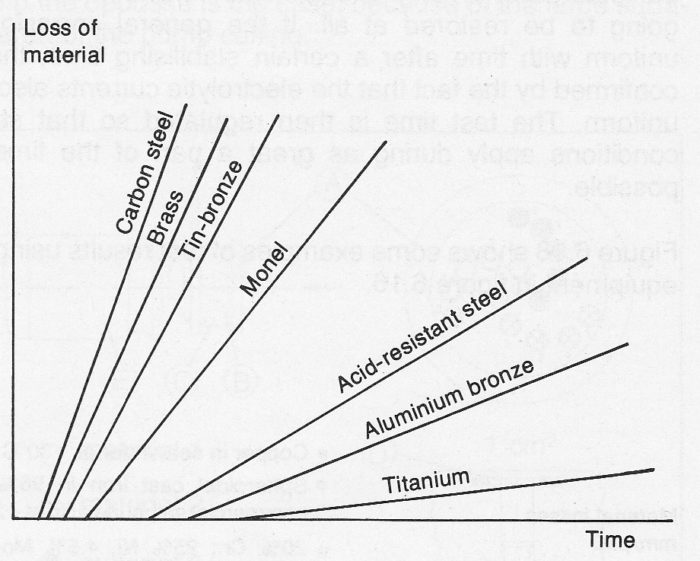

If this is not feasible or if the cavitation process is purposely used for regulation, as is the case for certain condensate pumps, then cavitation-resistant material has to be used. Choice can be made by studying the results of comprehensive series of experiments, see figure 4.5b. As shown in this figure, it takes a certain amount of time before cavitation damage appears. The process is similar to the incubation time for some infectious diseases.

Figure 4.5b The resistance of various materials to cavitation