6.11 Pump motor IP class

Pump motor IP class

Pump motor IP class is a protection classification that states electrical equipment enclosure to particles and liquids. IP stands for Ingress Protection Rating (sometimes called Insulation Protection) or International Protection Marking and the IP class specifies the degree to which an electrical enclosure, such as a pump motor, is protected against the intrusion of solid objects and liquids.

IEC 60529 (International Electro-technical Commission) classifies the types of enclosure for rotating electrical machines in respect of the degree of protection afforded to persons against contact with live parts, and against ingress of solid foreign bodies and liquids. Solid particle protection is defined as the level of protection that the motor enclosure provides against access to hazardous machine parts such as moving parts and electrical components. Liquid ingress protection is defined as the level of protection against the entrance of water into the motor. This is especially useful in the case of pumps. ISO 20653 Protection of electrical equipment against foreign objects, water and access is also a reference to IP class rating, however, not so commonly addressed in pump industry.

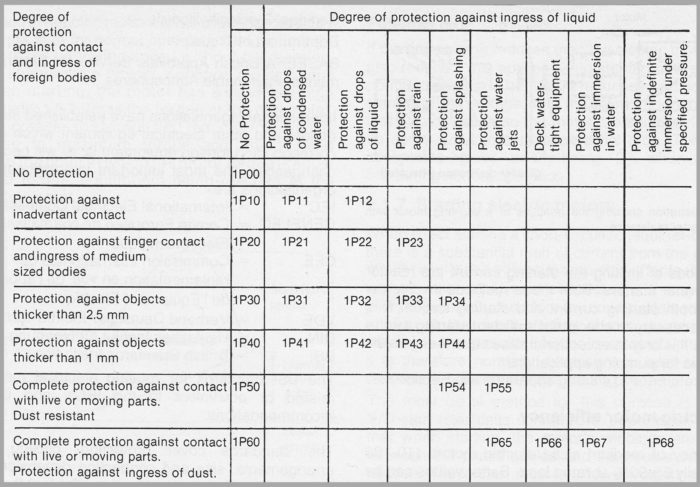

The protection category required for an electric pump motor depends, of course, upon the surrounding environment. All electrical installations must comply with the relevant statutory requirements. The various types of classifications are designated by using the letters IP followed by two figures. The digits indicate conformity with the conditions, see figure 6.11a below. The digit 0 is used where no protection is provided. The digit is replaced with the letter X when insufficient data has been gathered to assign a protection level.

Using a combination of the ratings in the table below, gives us an IP rating stating the pump motor protection levels. For example, IP67 means that the enclosure is dust tight, with complete protection against contact, and also is able to be immersed in one meter of water for up to 30 minutes.

The table in figure 6.11a reviews the standard designations for various IP class protection categories.

In certain cases electric motors must be equipped with condensation drainage facilities, usually by boring a 6-8 mm diameter hole at the lowest point. To protect electric motors against dripping water or mechanical damage the fitting of special shields may be necessary. For that reason, in some situations, a lower IP class may be more suitable than a higher IP. For example, IP 44 motors can be more suitable than an IP 55 motor in a damp environment where condensed vapour can form in the stator housing. Drain holes in an IP 44 motor allow the moisture to drain out of the stator housing, which would not be possible in an IP 55 motor.