3.2.9 Marine pumps

Marine pumps

Marine pumps are included as important components in, not only ships and oil rigs, but also underwater equipment. Pumps for ships can be classified as follows:

- Systems for propulsion, e.g. pumping fuel, lubrication oil, coolant water, feed water and condensate.

- Systems dependent on the ships themselves and/or the cargo, e.g. in pumping ballast water and/or fluid cargoes.

- Safety systems, e.g. for bilge pumping, for the fighting of fires, explosions, poisons etc.

- Remaining systems for pumping drinking water, sewage etc.

Due to the fact that ships at sea should be able to function safely and entirely independently, special requirements are made on equipment which has to do with the safety of ships. These requirements are determinated by marine

insurance companies (classification) and each country’s respective maritime authority. In certain cases additional requirements are put forward by, for example, port and canal authorities. Various types of pumps are used for the aforementioned pumping systems in the same manner as in the case of land based systems.

A typical feature of centrifugal pumps on board, is that they are often of the vertical type in order to reduce the space requirements, mechanical design is adapted to take account of the ship’s movement at sea and automatic, separate or built in evacuation systems are present in order to avoid operational problems in the case of long suction lines or if the suction intake is momentarily above the surface of the liquid. As a general rule, bronze or red brass is used when pumping sea water and the same material as in the case of land based systems is chosen for other fluids.

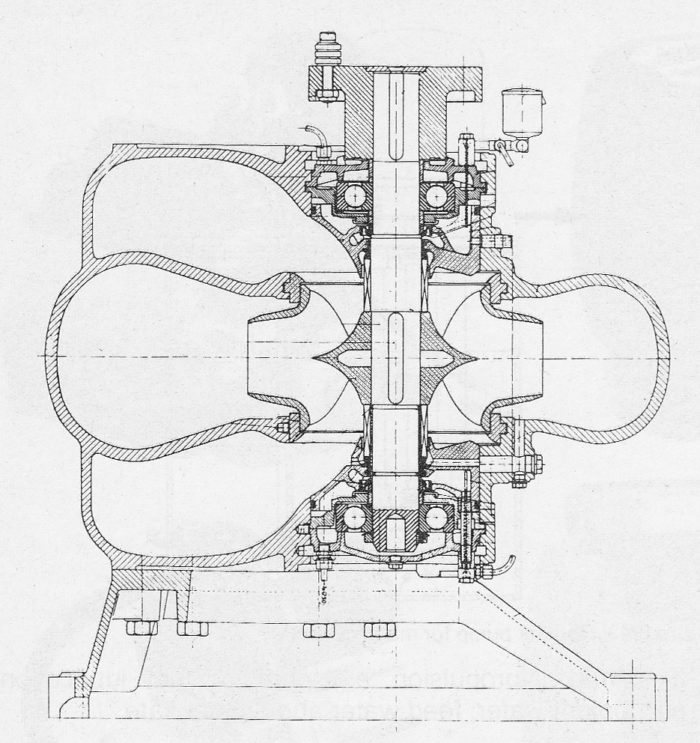

Figure 3.271a shows a typical vertical pump for general use on board ship. This is a double suction pump with the pump casing divided axially (in a vertical plane) in order to facilitate servicing. Single suction impellers with axially or radially divided pump casings are used for smaller volume flows. In the case of a radially divided pump housing, the pump’s rotor should be able to be disassembled in a simple manner, compare for example, figure 3.22c.

In the section Case Studies the installation of cargo oil pumps are shown as a practical example.

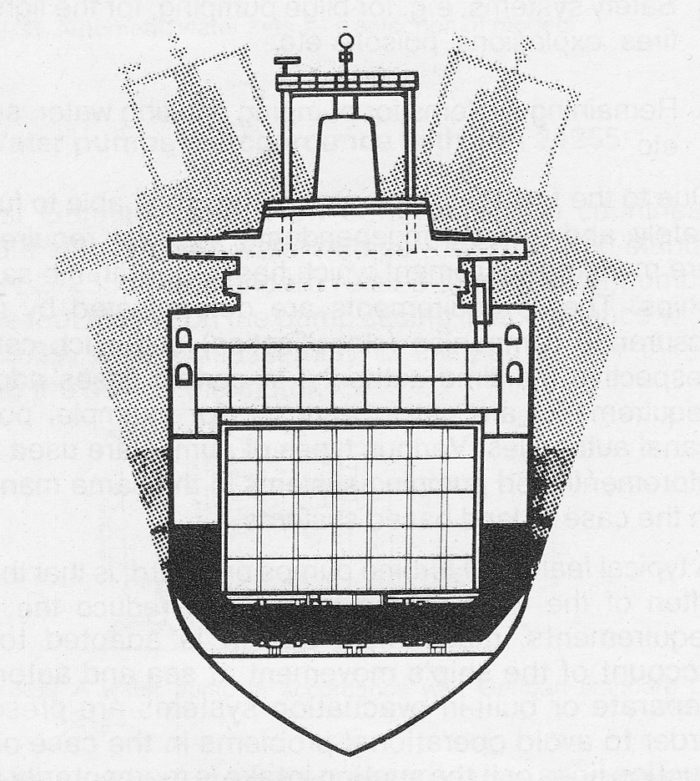

For marine use. there are many interesting applications of pumps. for example, for jet operation of non-anchored oil rigs with automatic positioning. A pump system as shown in figure 3.271b and constructed of axial pumps designed to operate with any flow direction, is used to limit heeling when loading, for example, or for the intentional generation of heel angle in the case of icebreakers.