3.5.2 Air lift pump

Air lift pump

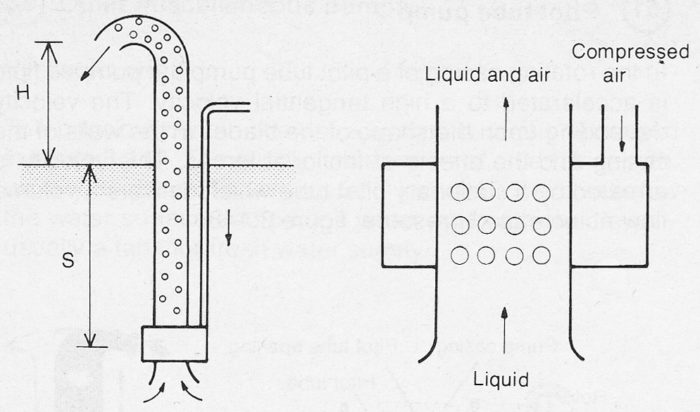

The air lift pump consists of a riser tube immersed in the pumped liquid, a compressed-air line and a pressure chamber where air forces the liquid, via small holes into the riser tube, figure 3.52a. The air liquid mixture is lighter than the surrounding liquid and therefore rises up the tube. The flow of liquid up the riser tube increases as the flow of air is increased up to a certain maximum value, after which it begins to decrease again.

The air supply must be compressed to a pressure which is equivalent to the immersed depth plus the losses in the piping and inlet holes. The product of the work done during compression and the air mass flow, neglecting the efficiency of the compressor, is equal to the power input to the pump Pinput.

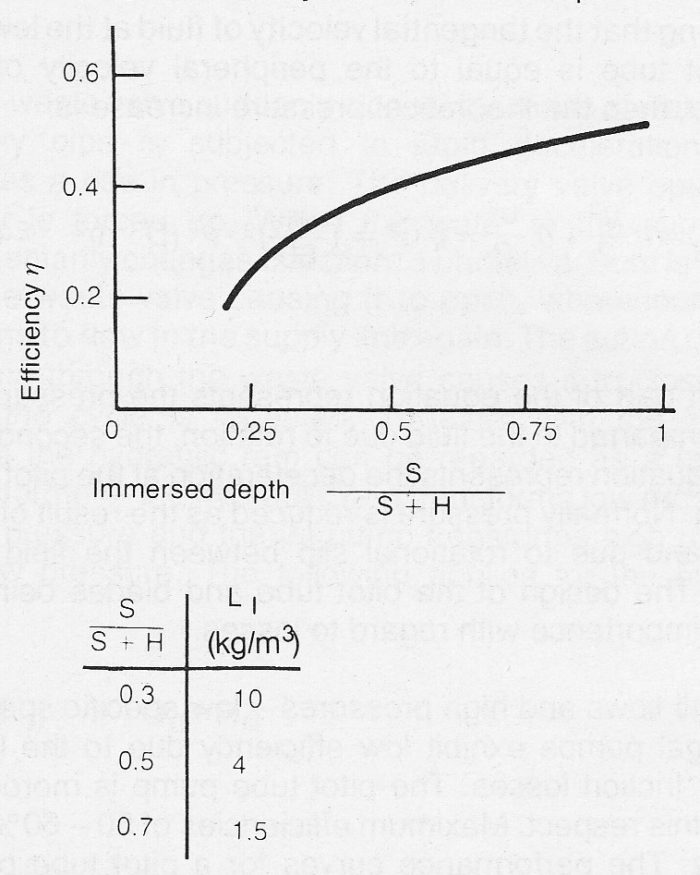

The pump efficiency

is greatly dependent upon the immersed depth in relation to the delivery head, figure 3.52b. The quantity of air required in kg per cubic metre of pumped liquid, designated L, is greatly affected by the immersed depth.

Figure 3.52b shows example of the maximum efficiency in an air lift pumps, neglecting compressor efficiency, and estimated air requirement.

The advantages of the air-lift pump are:

- Simple construction, no moving parts

- No sealing problems

- Small risk of blockage

- Not sensitive to temperature

The disadvantages of the air-lift pump are:

- Low efficiency

- Immersed depth requirements (S/H > 1)

- Compressed air can be expensive

Air-lift pumps are used for pumping sludge, contaminated liquid, large particles like sugar beets and also hot or corrosive fluids.