3.74 Central heating circulation pump

Central heating circulation pump

Central heating circulation pump, circulates a flow which is nearly constant in time. Available pumps are usually too large and can cause flow noise. This is avoided by using pumps with built-in flow adjustment by throttling, by-pass, shunt or speed regulation.

Choose a wet rotor pump to avoid shaft seals. Usual pump capacity or power class is 25 W shaft output for small dwellings which means about 60 W input (power requirement). For larger installations where larger flows deems necessary, larger pumps are needed. The system described here is typical for Scandinavian and Continental heating systems. Modern systems have room temperatures controlled for each room by a thermostat regulating valves and supplying the required heat to the rooms individually.

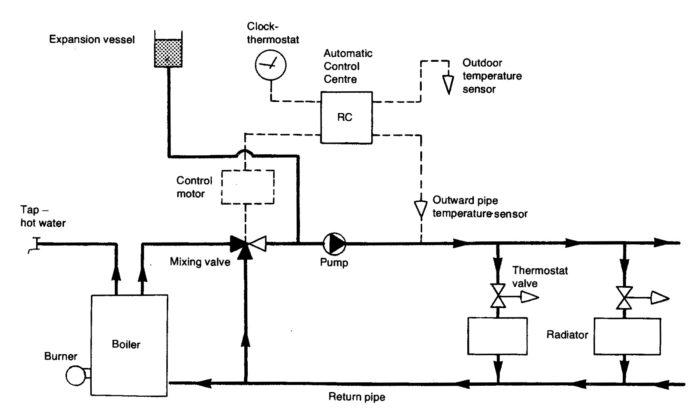

The burner/heater is operated on an on-off basis, the aim being to maintain a constant boiler temperature. The expansion vessel absorbs changes of volume in the water and maintains a suitable excess pressure in the system in order to avoid cavitation.

Pipes are dimensioned in accordance with piping standards. Pipe materials are typically copper or steel. The figure above shows a double-pipe system. Single-pipe systems are also in operation.

Radiators transfer heat to the air in rooms. Suitable distribution of flow to the radiators is preadjusted by means of fixed throttles. Modern central heating circulation pump system installations doesn’t use radiators but hoses are installed in the floors.

Hot water for taps meet requirements for washing up, showers, baths, etc.

Mixing valve, regulates forward pipe temperature by admitting return water. Often located close to, or built into, the boiler. Reduces the forward temperature at night or other desired time when a lower temperature is acceptable.

Automatic control center receives signals from the forward pipeline temperature and outdoor temperature sensors. Adjusts via the mixing valve a suitable outward pipeline temperature as a function of the outdoor temperature. In this way a more even room temperature is obtained and a decrease of the room temperature at night is made possible.

Thermostat valves throttle the flow to radiators, or to each separate hose for each loop/room, thereby permitting individual room temperature adjustment. Also make allowance for additional heat from the sun, electric sources, etc.

Design temperature varies but forward pipe temperature is normally approx. 60-80 °C, with return pipe approx. 40-60 °C, Δt = 20°C. The heat required is dimensioned in accordance with outdoor temperature.

Pitfalls

Check the rotation direction of the pump when installing. The ingress of contaminants from pipes during installation and corrosion products from boiler and pipes causes wear to the pump bearings. Heat up the system and drain it before finally putting into operation. After long periods of disuse the motor can jam in its bearings.