4.6 Choice of material for pumps

Choice of material for pumps

This is a check list of information necessary for choice of material for pumps. A review of rough choice of material can be found here but see also section 10 about Properties of Liquids. This information enables the selection of materials suitable for large groups of liquids. In more specific cases, it is recommended that a study should be made of special literature and data tables of the properties of the specific liquid in question. It is, however, inevitable that even this background check up will not be adequate in many special cases, so that judgement has to be made based on practical experience of similar cases.

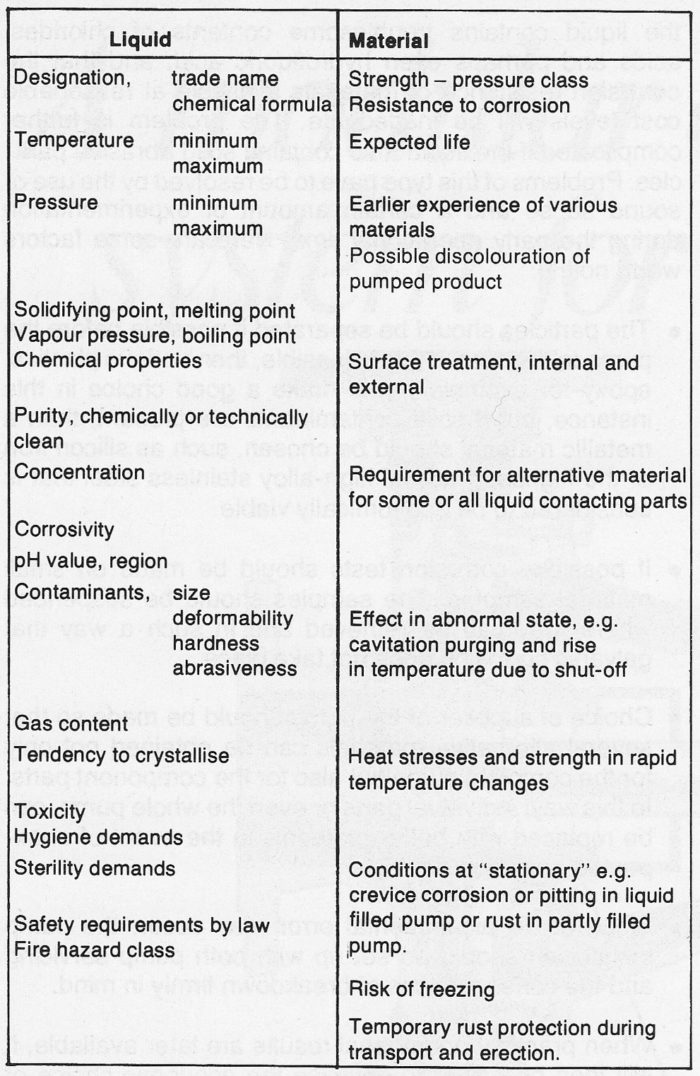

The information required for choice of material has been collected in figure 4.6a in the form of a check list.

Combinations of materials

Since some components more than others in a pump are subjected to stress, it is natural that these should be made of better materials. It may also be necessary for parts which are in permanent or occasional contact to have good bearing properties. This is the case in displacement pumps or with the unwished for contact between pump impeller and casing in centrifugal pumps. Generally speaking, the materials should differ completely, but if they are the same, their Brinell hardness figures should differ by at least 30.

There is a certain established practice for combinations of materials in centrifugal pumps. This requires that pump impeller and sundry small parts shall be made of better material than the casing. In the case of shafts, attention must be paid to corrosion fatigue, which occurs with relatively small corrosive attacks and, in time, causes the shaft to break. An alternative is to seal the shaft off completely from the liquid.

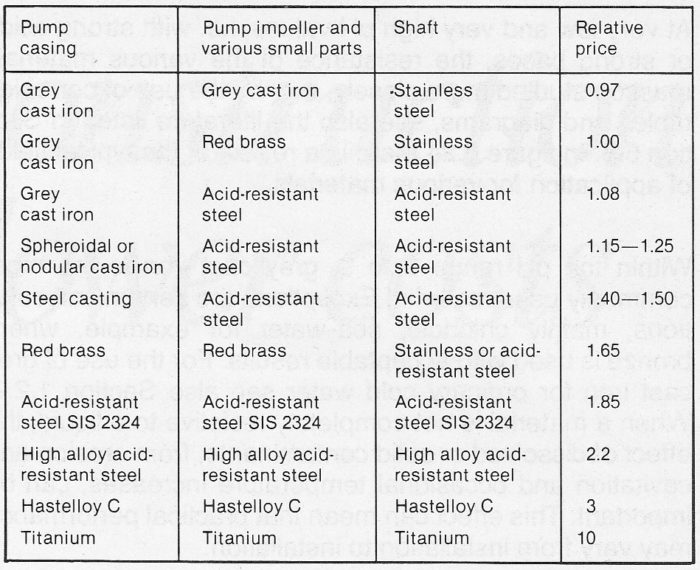

There are three different impeller materials for use with the simplest pump casing material grey cast iron, as shown in figure 4.6b. When the impeller is made of grey cast iron, there is a risk of rusting up after a test run, or whenever the pump is still. A better choice of material for the impeller would be red brass or acid-resistant steel. If the pH value of the liquid is more than 8 to 9 then red brass is not sufficiently resistant. Figure 4.6b shows the relative costs of the various materials. This intends only to show an approximate picture of price levels, since the cost ratios depend on size of pump, basic prices for the various metals and so on.

Figure 4.6b Some commonly used combinations of materials for pumps. If the shaft is sealed against the liquid, it can be made of lower grade metal.

Choice of material with regard to corrosion

From the point of view of corrosion, the choice of materials is made from two entirely different viewpoints:

- The material selected must support the intended life duration for the pump equipment.

- The material should also be such that the process in which the pump is included as an aid, is not materially affected. Examples of effect on processes can be anything from rusty water in a drinking water installation, to poisoning of catalysts in a chemical process because of corrosion products from the pump. The process effect can thus rule out some materials in certain cases, even though they, in themselves, have an adequate resistance to corrosion.

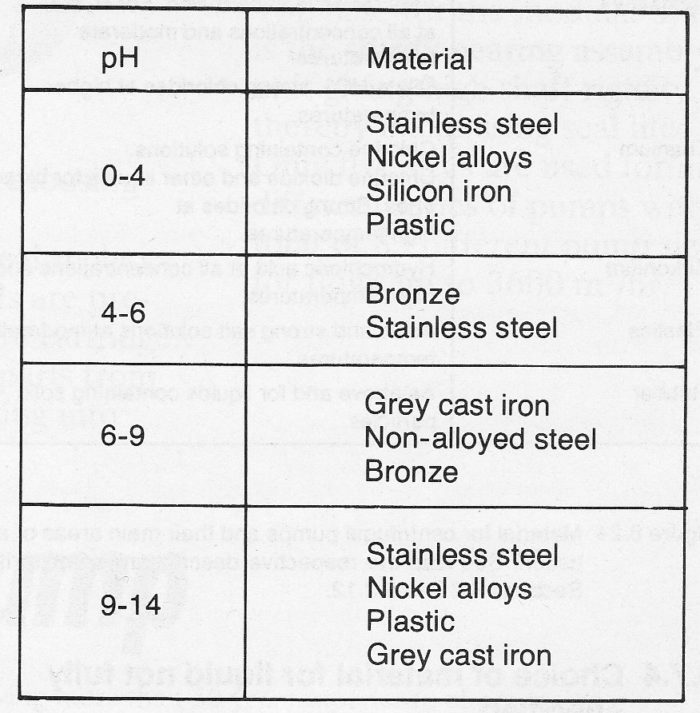

When it to corrosion from chemicals in aqueous solutions, it is the pH value and the liquid temperature which provide a preliminary guideline for choice of material for pumps, see figure 4.6c.

Figure 4.6c pH value and choice of material for liquid temperature 0°C to 50°C

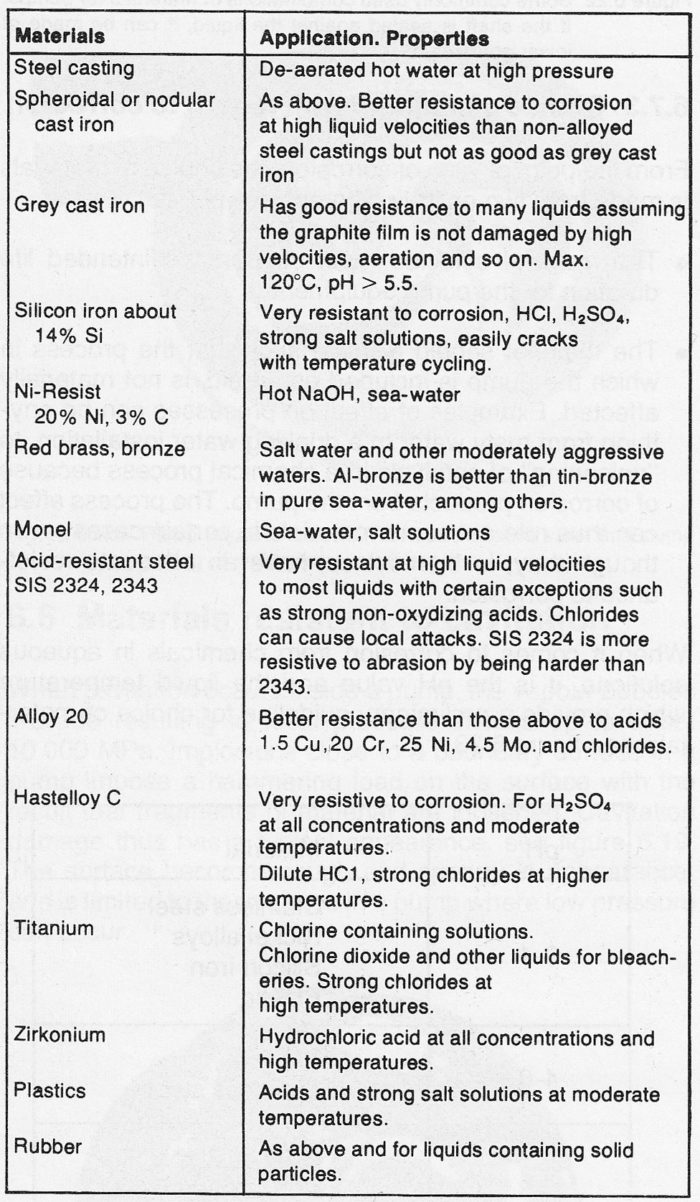

At very low and very high pH values, i.e. with strong acids or strong bases, the resistance of the various materials must be studied more closely, e.g. by the use of corrosion tables and diagrams. In figure 4.6d there is a review of the typical fields of application for various materials.

Within the pH range 6 to 9, grey cast iron is the most commonly used material. Exceptions are certain salt solutions, mainly chloridic, sea-water for example, where bronze is used with acceptable results. For the use of grey cast iron for ordinary cold water see also Section 10. When a material is not completely resistive to a liquid, the effect of dissolved or solid contaminants, from erosion and cavitation and occasional temperature increases, can be important. This effect can mean that practical performance may vary from installation to installation.

Figure 4.6d Material for centrifugal pumps and their main areas of application. See also the respective descriptions of materials in previous pages 4. Material for pumps

Choice of material for liquid not fully specified

In some cases it is practically impossible to specify the liquid to be pumped. A typical example of this is the various residues and effluent from, say, the plating industry. In this case, the only known conditions may be that the liquid contains troublesome contents of chlorides, acids and perhaps even hydrofluoric acid, and that the corrosion resistance of materials available at reasonable cost levels will be inadequate. The problem is further complicated if the liquid also contains solid abrasive particles. Problems of this type have to be resolved by the use of sound sense and certain amount of experimentation during the early operational time. Here are some factors worth noting in choice of material for pumps when liquids not fully specified:

- The particles should be separated if possible before the pump takes over. If this is feasible, then various plastics, epoxy for example would make a good choice in this instance, but if solid are present, then a metallic material should be chosen, such as silicon iron or the highest grade of high-alloy stainless steel that is considered to be economically viable.

- If possible, corrosion tests should be made on small material samples. The samples should be suspended where they can be retrieved and in such a way that galvanic corrosion does not take place.

- Choice of supplier of the pump should be made so that several alternative materials can be obtained not only for the complete pump but also for the component parts. In this way, individual parts or even the whole pump, can be replaced with better materials in the event of unexpected corrosion damage.

- Since some experimental error may occur, the pump installation should be set up with both pump servicing and the consequences of breakdown firmly in mind.

- When practical operational results are later available, it will then be easier to optimize the economic choice of material, balancing life duration and procurement costs of various materials.