5.5 Maintenance and trouble-shooting a pump seal

Maintenance and trouble-shooting a pump seal

Maintenance and trouble-shooting a pump seal is compulsory for every pump owner operator. The operating life of a seal is limited and primarily dependent upon selecting the right seal and the right material, i.e. the optimum with regard to the type of duty. The service life as well as the leakage rate are further influenced by the condition of the pump and its design and by the manner in which it is operated, continuous or intermittent, etc

It can be generally stated that the operating life of a mechanical seal and shaft sleeve in a soft stuffing box packing is approximately the same, for pressures up to 1 MPa, an estimated 3-4 years average operating life. In the case of soft stuffing box packings this is only achieved by careful maintenance and adjustment the results being very dependent on the people who do the job. A mechanical seal, on the other hand, requires no subsequent adjustment and if installed correctly from the beginning, provides trouble-free operation. At pressures above 1 MPa the service life of soft packings decreases since they cannot be balanced as in the case of mechanical seals.

Maintenance

Regular maintenance of the soft packing consists of a daily leakage inspection and tightening of the gland if necessary. When leakage has risen considerably, or where further adjustment can no longer be made, then repacking becomes necessary, i.e. all the rings must be replaced. Repacking can be delayed, in the case of emergencies, by inserting a further packing ring, this is not to be recommended, however. When the shaft or shaft sleeve is well worn then repacking without replacing this part is as good as useless.

Regular maintenance of a mechanical seal is limited to checking for leakage once a week. From the point in time when leakage appears as drops, the seal can usually be operated for a week or two before it needs to be replaced.

For both types of seal it is necessary to check the function of any auxiliary cooling, or barrier fluid system, etc.

Trouble-shooting, soft packings or stuffing box

Below is a number of indications as well as the probable cause and actions for remedy that can be used for trouble-shooting a stuffing box / soft packing. The suppliers of packing materials can usually provide further information and advice as well as practical training.

Legend for trouble-shooting stuffing box

- Indication

- Probable cause

- Action

- Probable cause

Trouble-shooting scheme for stuffing box / soft packings:

- The packing has extruded between shaft and gland or box bottom

- The clearance is too large which can be due caused by wear or poor bearings

- Reduce the clearance Check the clearance

- The clearance is too large which can be due caused by wear or poor bearings

- Leakage on the outside of the gland

- The packing is badly installed or the surface of the box is in poor conditions

- Repack after checking the surface of the box

- The packing is badly installed or the surface of the box is in poor conditions

- The outside of the packings are scored

- Wrong dimension

- Check that the right dimension is used

- Wrong dimension

- The packing goes into adjacent rings

- The packing is cut too short

- Check that the right length is used

- The packing is cut too short

- The rings nearest to the gland are compressed very hard

- The packing is wrongly installed

- Tighten a couple of rings at a time when installing

- The packing is wrongly installed

- Burnt packings

- Dry running or poor lubrication. Possibly due to excessive tightening

- Change packing quality & Supply barrier fluid

- Dry running or poor lubrication. Possibly due to excessive tightening

- The packing is swallowed up or dissolved

- The packing does not withstand the pumped medium

- Change packing quality

- The packing does not withstand the pumped medium

Trouble-shooting mechanical pump seals

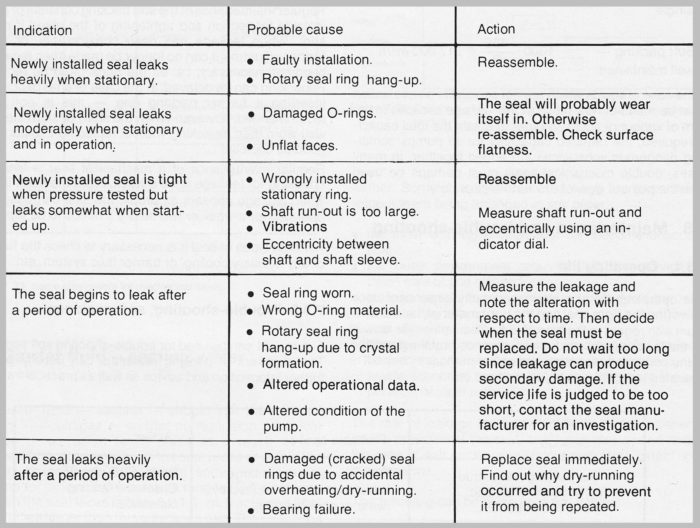

Leakage is the only indication of a faulty mechanical seal. In order to be able to evaluate if and when the seal must be dealt with, it is not sufficient to notice leakage. The occurrence of leakage does not provide sufficient information as to the course of action to be taken. It is also necessary to evaluate the circumstances, when and where, and the appearance of the leaking liquid. Figure 5.5a reviews some typical examples. In more difficult cases the seal manufacturer should be contacted and he should also be present when it is disassembled since the fault symptom can easily disappear during disassembly.

Figure 5.5 Trouble-shooting scheme for mechanical pump seal.