4.1 Material strength and leak-tightness under pressure

Material strength and leak-tightness under pressure

Material strength and leak-tightness under pressure is an important factor when choosing materials for pumps working with the kinds of fluids which could cause accidents in some way are subject to the current regulations for pressure vessels. The static strengths of pumps are grouped in pressure classes for example PN 10, 16, 25 and so on, where the digits refer to the highest pressure in bars. (1 bar = 100 kPa = 0.1 MPa). Pressure testing is done by the manufacturer usually at a pressure 30% higher than the classification. For standard pumps in accordance with ISO 2858 it is 1.5 times the highest outflow pressure, together with a correction factor for liquid temperature as agreed between the supplier and the user.

Pressure testing can sometimes not be carried out on a fully assembled pump for such reasons as:

- the shaft seals not being made to the pressure class of the pump, because during operation the seal is possibly only loaded to a fraction of the value of the pressure class

- the axial forces generated by the pressure testing possibly causing damage to the axial bearings carrying the through-shaft.

In principle, the pump has to be liquid-tight, for the pressure test, and yet there is no real criterion for tightness. Sometimes it is given as no drops appearing after 5 minutes of sustained pressure.

It is difficult to assess the extent to which the sealing of minor leakages should be carried out. By and large the following should apply:

- For qualified pumps, it is permissible to repair minor defects in the material by welding with the same material as the basic material. When welding and carrying out subsequent heat treatment care must be taken to observe the appropriate instructions relating to the particular material specification.

- Caulking is permitted, but it is dependent upon the material, liquid and demands on the pump.

- Sealing by impregnation using various liquids, plastics, water glass or special chemicals, is approved practice for certain light metal alloys but is particularly doubtful or completely forbidden for many other materials.

The strength of a pump is determined by a combination of effects from the internal pressure and the forces and moments acting on the connecting flanges and, in certain cases, the forces from the drive motor as well.

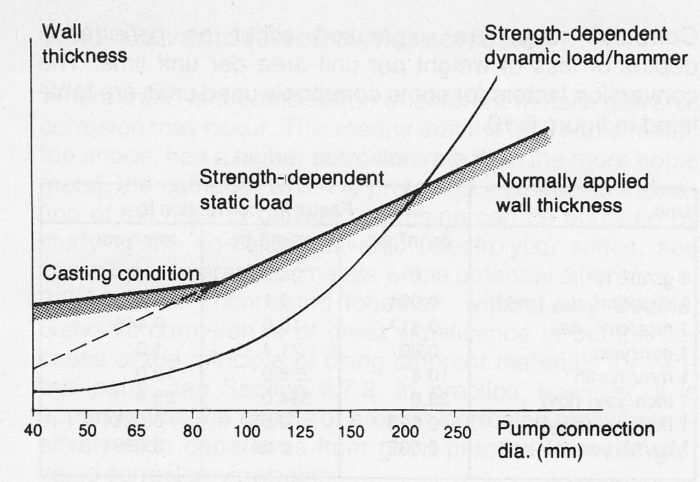

The internal positive pressure comprises the sum of inflow pressure, the maximum increase of head by the pump and an amount dependent on line shock (water hammer). The total positive internal pressure must be less than that permitted for the pressure class. In practice, strength depends on the size of the pump. In general, small pumps are over-dimensioned, whilst large ones can be very sensitive to dynamic loading from pressure shocks, figure 4.1a. In the case of large pumps, it may make sense to use tougher material such as spheroidal or nodular cast iron instead of brittle material such as grey cast iron.

Where pumps are subjected to Standards for Pressure Vessels, choice of material should be made with elasticity, and sometimes even shock resistance, in mind.

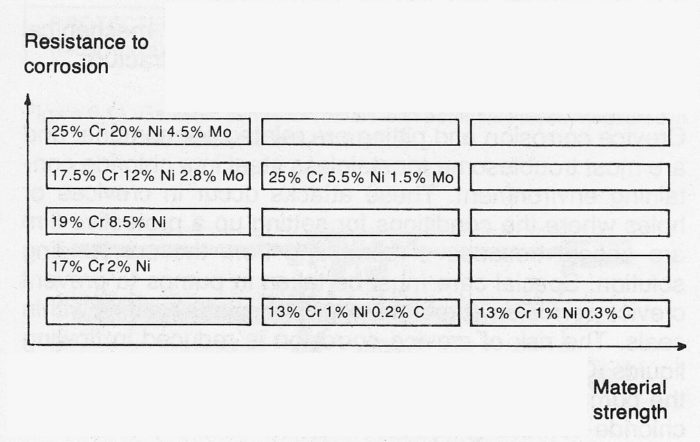

Figure 4.1b shows, by taking examples of stainless steel, how many material qualities may be called upon to cover the various demands on strength and resistance to corrosion.

Figure 4.1b Distribution of a number of stainless steel specifications relative to strength and to corrosion. Empty blocks are covered by individual makers special qualities.

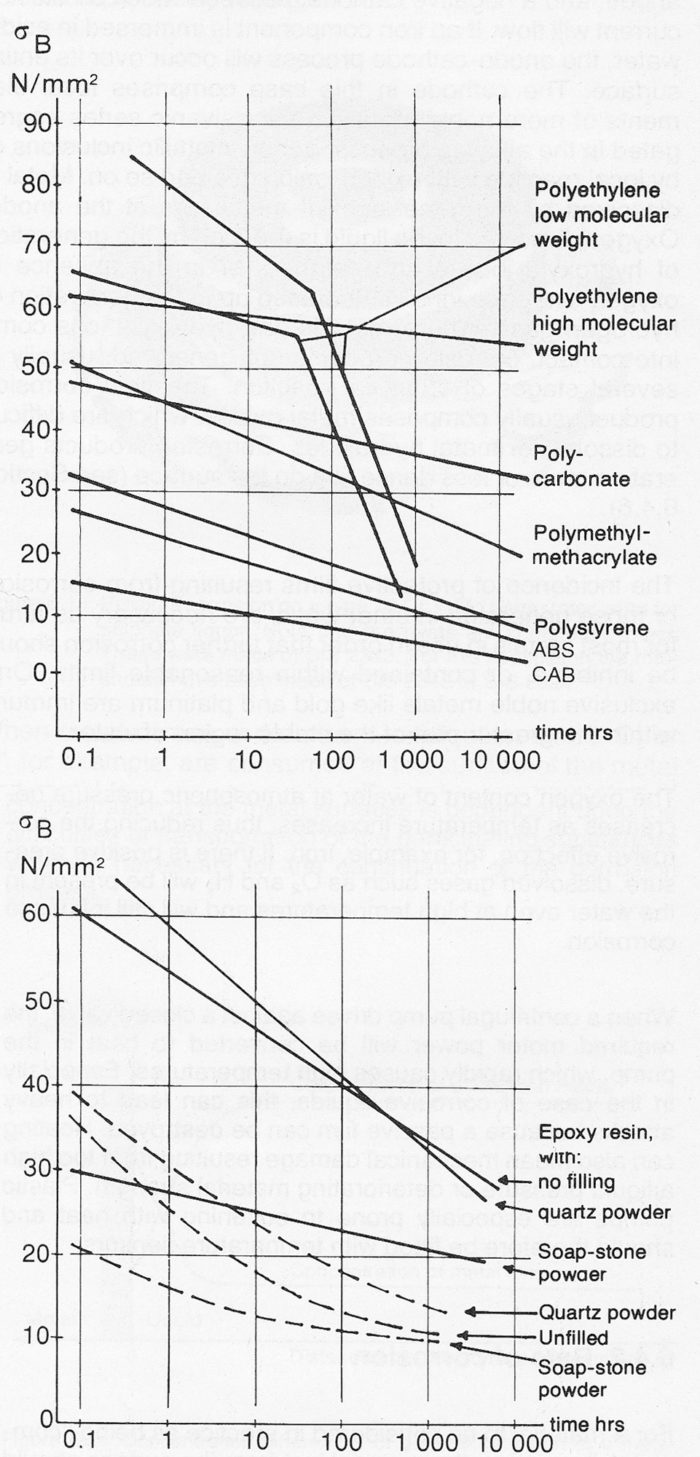

In the case of plastic materials, the strength diminishes dramatically with time, so-called creep. The process is at higher temperatures and also in liquids. Figure 4.1c shows some values for creep in air. When procuring plastic pumps, particularly for use with hazardous liquids, relevant information should be obtained for the actual liquid from the pump or material supplier.

Figure 4.1c Static durability for various plastic materials, temperature 23°C and 60°C

Figure 4.1c