3.5.7 Peripheral pump

Peripheral pump

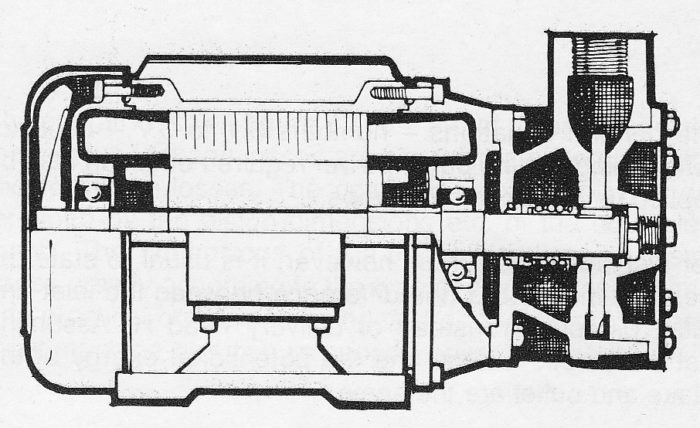

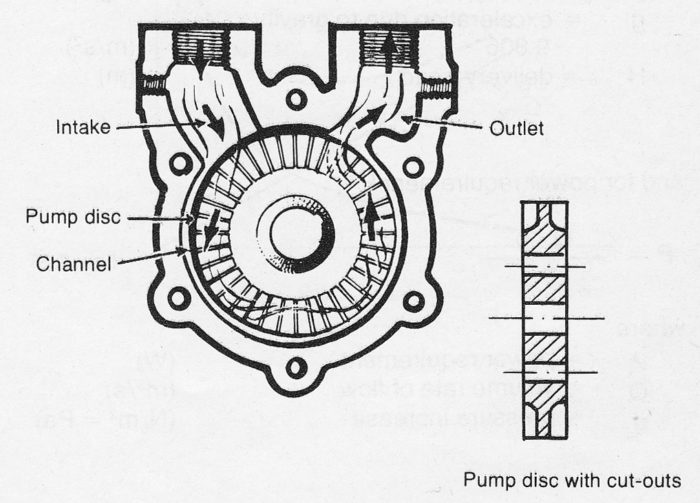

Peripheral pump occupy together with Liquid ring pumps a position between Rotodynamic pumps and positive displacement pumps. Their method of operation having some of the characteristics of both types. Peripheral pumps are also called turbine pumps, or regenerative pumps. The description turbine pump can, however, cause confusion with vertical multi-stage semi-axial pumps for use in boreholes. The action of the pump is similar to that of a liquid ring pump. The difference is that the vanes are greater in number and are mounted on the periphery of the rotating disc. In practice the vanes are formed by making cut-outs in the periphery of the disc and supply energy during almost a complete revolution. The pressure head increase is greater for a given outer diameter than for liquid ring pumps. Other characteristics and applications are however similar. A section through a single stage regenerative pump is shown in figure 3.57a.

A peripheral pump can, unlike other centrifugal pumps, transport fluids with a relatively high gas content, known as two phase flow. Various flow patterns can occur in a two-phase flow depending on concentration ratio or mix of liquid gas content, slip ratio (difference between flow velocities of the gas and liquid) and piping configuration (horizontal, vertical). The efficiencies of peripheral pumps are lower than those of radial pumps. They are suitable for pumping pure uncontaminated liquids, e. g. as boiler feed pumps for small boilers, as pressure boosting pumps and for other applications in which low flow rates have to be pumped at high pressure.

Figure 3.57a Section through a single stage regenerative pump

Recirculation of liquid between the vanes of a regenerative turbine pump occurs a number of times between suction and discharge. The path of fluid travel can be thought of as an extended helical spring bent in a circle until its ends nearly touch. When the pump operates under low heads, space between the helical coils increases. On high heads the helix closes. That is, the fluid circulates more times in its travel from suction to discharge, a small bypass flow also occurs across the sealing surfaces between the discharge and suction. Wear on these sealing surfaces increases the clearances, increase the bypass flow and reduce pump capacity and efficiency. Most failures of turbine pumps are caused by this wear at the sealing surfaces, especially at high heads (high speed).

Figure 3.57b Regenerative pump