3.4.7 Piston pump

Piston pump

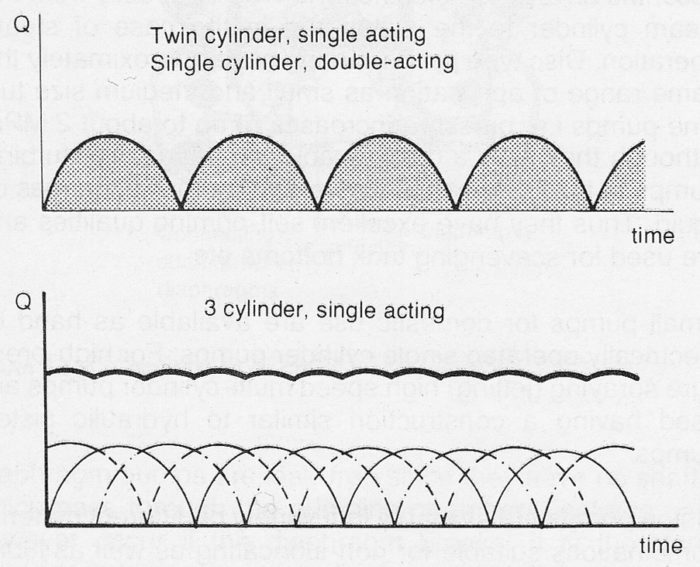

A piston pump can be single cylinder or multiple cylinder with single or double acting pistons. Single cylinder, single or double acting piston pumps are used for small volume rates of flow. Smoothness of flow in the suction and delivery pipelines can be achieved by employing a number of cylinders connected in parallel figure 3.27a, this also has a correspondingly smoothening effect upon the pump power input requirement. It is especially advantageous to use odd numbers of parallel connected cylinders such as 3, 5 or 7. To reduce flow variations and associated problems, e.g. vibrations and bending of the suction and delivery pipes, air cushion chambers (pulsation dampers also known as bladder ackumulator) may be integrated with the pump.

Figure 3.47a Flow variations for piston pumps are dependent upon the number of cylinders.

The following is a guide to the effective water volume Ve of a suction or delivery cushion chamber:

- Single acting pump 60% of total swept volume

- Double-acting pump 25% of total swept volume

- Three cylinder single acting 1 % of total swept volume pump

A volume of water must be added to the effective volume of water, which compensates for the compression of air to operating pressure (in the absence of pre-compression) and for the volume of air VA which is dependent upon the permissible degree of pressure non-similarity δP (= twice the relative pressure amplitude). The degree of non-similarity chosen is normally less than 0,10 for a suction cushion chamber and less than 0,05 for a delivery cushion chamber.

The air volume VA at maximum pressure is determined for isothermal conditions by:

where

δP = (Pmax – Pmin) / Pmean

Ve = Effective water volume (m³)

VA= Air volume at pmin (m³)

P = Absolute pressure (Pa)

It is important to obtain the correct volume of air in the cushions to avoid resonance between the natural frequency of the air cushion and the piston pump own stroke frequency per second or multiples thereof. The natural frequency of the air cushion also depends upon its size and even the size of the suction and delivery pipelines.

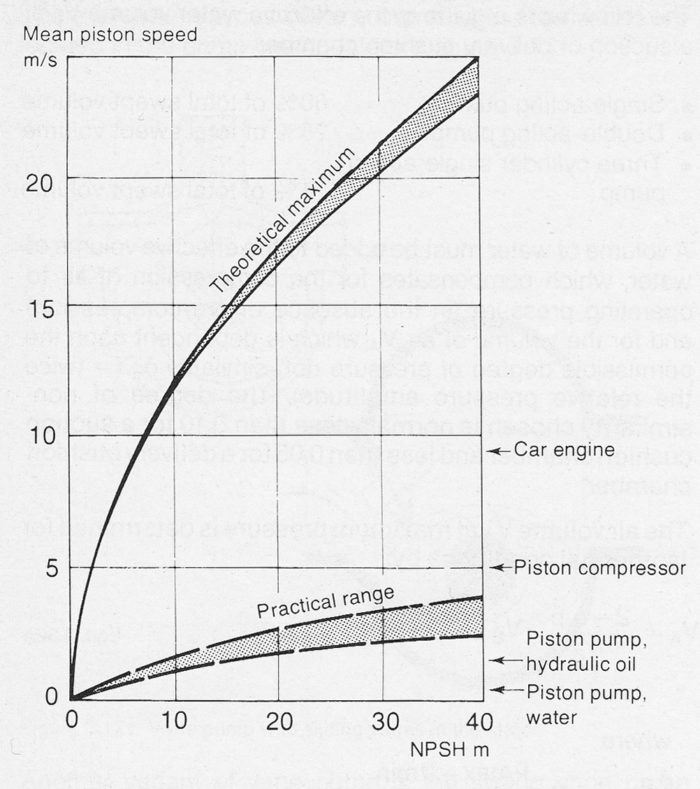

The number of strokes per minutes, n, for a piston pump is determined by the mean piston speed Vm (m/s), which is dependent upon stroke length, s in meters (m) according to the following:

Vm = (s * n) / 30 (Equ. 3.47b)

The mean piston speed determines the piston acceleration, which must not exceed the ability of the fluid to follow the piston movement. The mean piston speed is therefore dependent upon the NPSH value of the system, since the available instantaneous NPSH value is used to accelerate the fluid in the suction line and pump inlet ports. Valve loads and hammer shock in valves is also dependent upon the means piston speed. These are relatively low, normal values being 0,5 to 1 m/s, see figure 3.47b.

Figure 3.47b Theoretical limitation of mean piston pump speed with corresponding practical range.

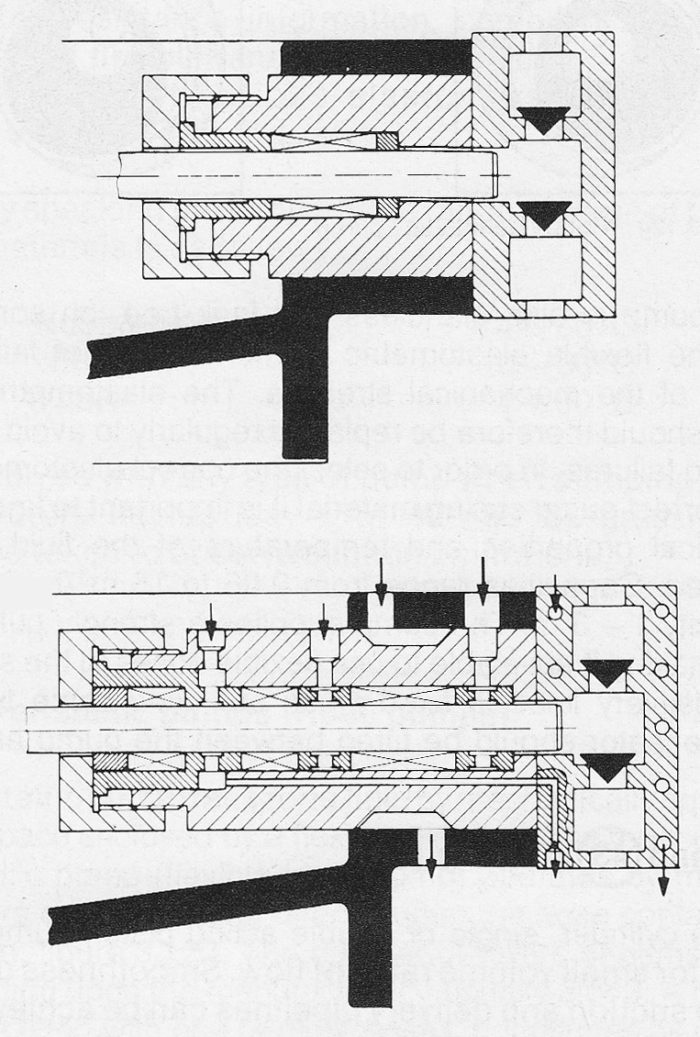

Piston pump valves are usually of the ball, poppet or disc type. The choice of material for the valve sealing surfaces is critical for large pressure increases. The valves are normally activated by fluid pressure with only a certain amount of spring assistance, although they can sometimes be operated by the drive mechanism. The piston proportions differentiate between plunger and disc piston modes, see figure 3.47c.

Figure 3.47c Piston pumps, the upper illustration shows the plunger type whilst the disc piston type is shown in the lower illustration.

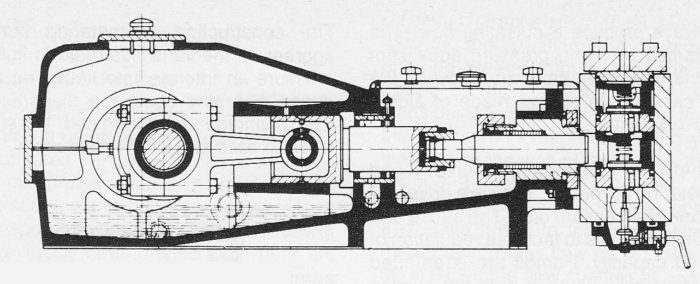

Plunger pumps are used for high pressures and very large pressure increases, up to 300-500 MPa. Sealing between the plunger and the cylinder is carried out by means of the direct action of the sealing element on the plunger, see figure 3.47d. The sealing element can vary from a simple soft packing to combinations of different seals with chambers for barrier fluids, flushing fluids and cooling fluids, figure 3.47d. The last mentioned type can handle virtually any type of fluid irrespective of contamination, toxicity etc. The drive mechanism, usually a crank is very elaborate for large pressure increases, in order to transfer and take up the large piston forces, figure 3.47e.

There are many special types of plunger pump for many different applications. Hence the so called concrete pump for pumping concrete on large construction sites with pressure increases of 2—5 MPa and volume flows of up to 200 m³/h. This is a plunger type pump, being normally hydraulically driven and often constructed with a special feeder and concrete agitator.

Figure 3.47d Sealing elements for high pressure plunger pump.

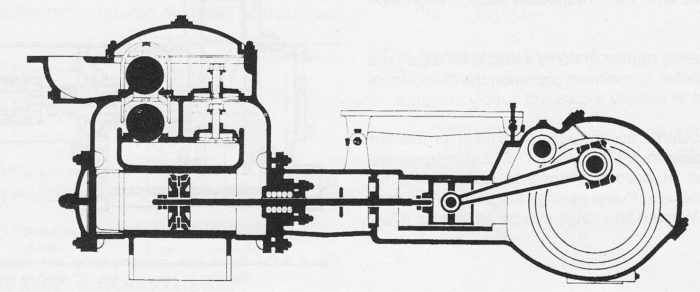

The disc-piston type of piston pump usually has a piston ring (piston seal) located in the piston. The piston is also fitted with a piston (connecting) rod, which in the case of a double acting pump is fed through a piston rod seal figure 3.47f. The pump is driven by means of a crank or eccentric drive when electrically driven or directly from the steam cylinder to the piston rod in the case of steam operation.

Figure 3.47e Plunger type pump for large pressure increases.

Disc type piston pumps have approximately the same range of application as small and medium size turbine pumps i.e. pressure increases of up to about 2 MPa, although they have a considerable advantage over centrifugal pumps in that they can just as easily pump either gas or liquid. Thus they have excellent self-priming qualities and are used for scavenging tank bottoms etc. Small pumps for domestic use are available as hand or electrically operated single cylinder pumps. For high-pressure spraying (jetting) high speed multi-cylinder pumps are used having a construction similar to hydraulic piston pumps.

Piston pumps are available in a variety of different material combinations suitable for non-lubricating as well as lubricating fluids. Viscosity range is very great, from water to thick flowing pastes.

Figure 3.47f Piston pump with disc piston for water etc.