3.5.5 Pitot tube pump

Pitot tube pump

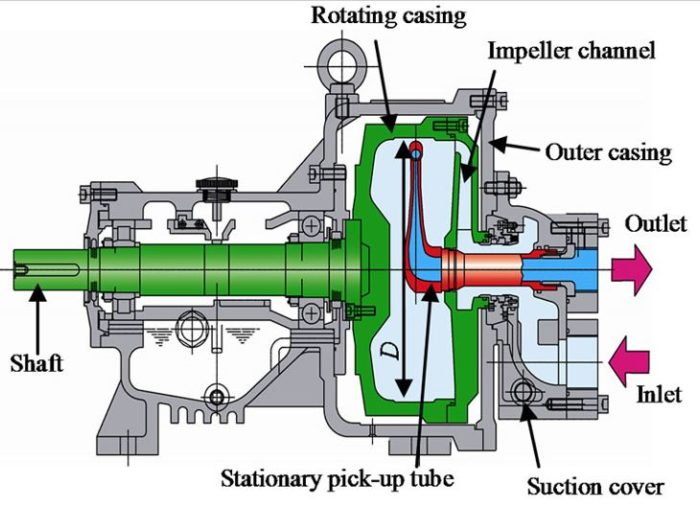

In the rotating casing of a pitot tube pump the pumped fluid is accelerated to a high tangential velocity. The velocity depending upon the shape of the blades in the walls of the casing and the effects of frictional forces. This velocity is

arrested by a stationary pitot tube which delivers a volume flow at increased pressure, figure 3.55a.

Figure 3.55a Pitot tube pump

Assuming that the tangential velocity of fluid at the level of the pitot tube is equal to the peripheral velocity of the casing u, then the theoretical pressure increase is:

The first part of the equation represents the pressure increase imparted to the fluid due to rotation, the second part of the equation represents the deceleration at the pitot tube opening. Normally pressure is reduced as the result of flow losses and due to rotational slip between the fluid and casing. The design of the pitot tube and blades being of special importance with regard to losses.

For small flows and high pressures, low specific speed, centrifugal pumps exhibit low efficiency due to the large impeller friction losses. Pitot tube pumps are more efficient in this respect. Maximum efficiencies of 50-60% are possible. The performance curves for pitot tube pumps are similar to those for a centrifugal pump. Safety valves, as a protection against overloading, are not necessary and the pump can be regulated by throttling.

Advantages of pitot tube pumps are:

- High pressure in a single stage

- Good efficiency for small flows

- Non-lubricating fluids can be pumped

The pitot tube pump cannot compete with the centrifugal pump for “normal” flows. Pitot tube pumps are not suitable for contaminated, abrasive or viscous fluids. Capacities of up to several hundred litres per minute and pressures of up to approximately 7 MPa are usual. Practical applications are high-pressure washing, water spraying and feed water etc.