3.4.14 Plunger pump

Plunger pump

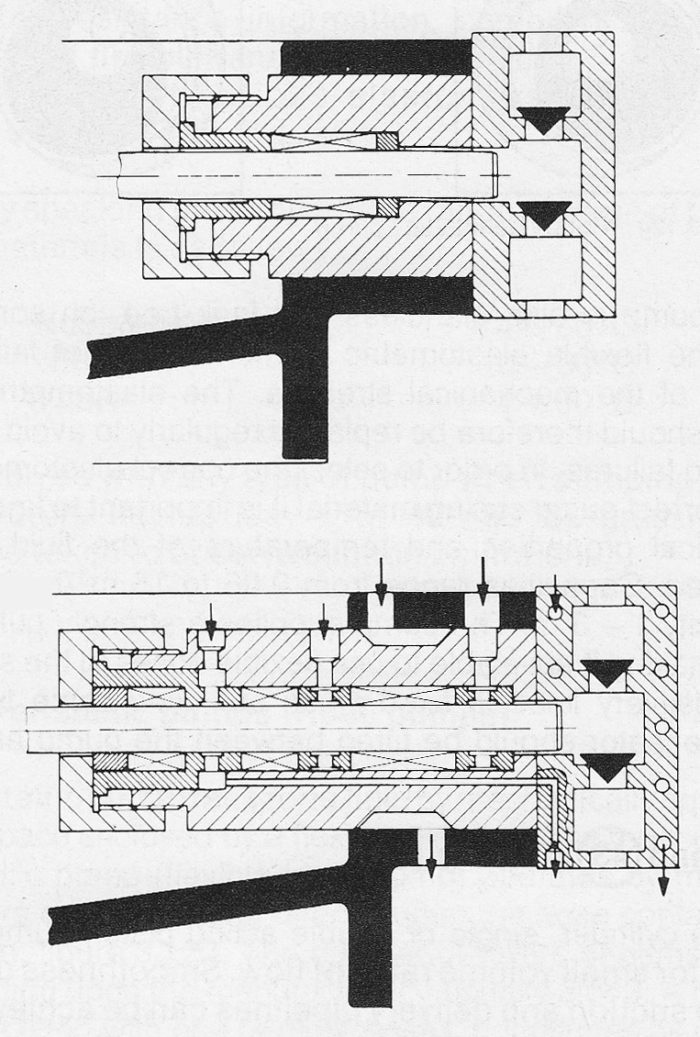

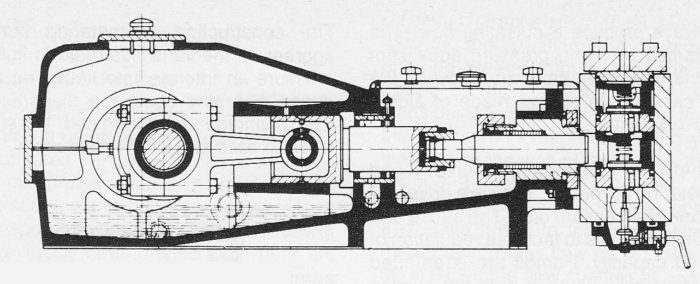

A Plunger pump is used when high pressures and very large pressure increases are required, up to 300-500 MPa. Sealing between the plunger and the cylinder is carried out by means of the direct action of the sealing element on the plunger, see figure 3.414a. The sealing element can vary from a simple soft packing to combinations of different seals with chambers for barrier fluids, flushing fluids and cooling fluids, figure 3.414a. The last mentioned type can handle virtually any type of fluid irrespective of contamination, toxicity etc. The drive mechanism, usually a crank is very elaborate for large pressure increases, in order to transfer and take up the large piston plunge forces, figure 3.414b.

There are many special types of plunger pumps for many different applications. Hence the so called concrete pump for pumping concrete on large construction sites with pressure increases of 2—5 MPa and volume flows of up to 200 m³/h. This is a plunger type pump, being normally hydraulically driven and often constructed with a special feeder and concrete agitator.

Figure 3.414a Sealing elements for high pressure plunger pumps.

Plunger pumps belongs to the piston pump family and it is the piston proportions and seal that differentiate between piston and plunger models, see figure 3.47c. Plunger pumps seals are stationary and the cylindrical plunger slides smoothly through the seal. This makes them different from piston pumps and allows them to be used at higher pressures.

Figure 3.414b Plunger type pump for large pressure increases.

The volume flow is equal to the area of the plunger, multiplied by stroke length. The overall capacity of plunger pumps are calculated the same way as for piston pumps. It can easily be calculated with the area of the piston or plunger, the stroke length, the number of pistons or plungers and the speed (number of strokes) of the drive. The power needed from the drive is proportional to the pressure and capacity of the pump. Read more about this on the page for Positive Displacement Pump Theory