3.4.3 Progressive cavity pump

Progressive cavity pump

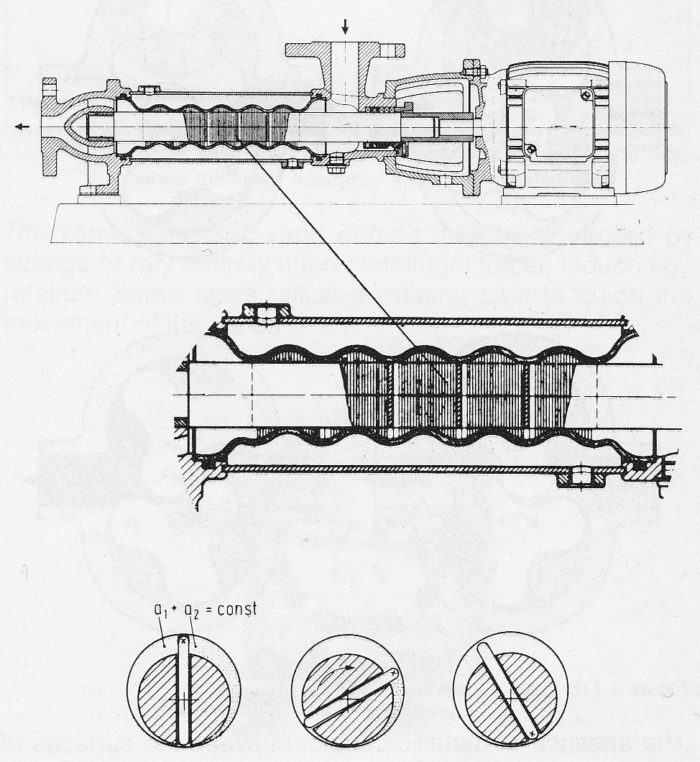

Progressive cavity pump (also known as PC pumps) has only one screw working within a rubber stator. The screw, which looks something like an elongated corkscrew, rotates in a stator having double internal helixes. The pitch of the stator thread is twice that of the rotor. This forms sealed cavities between the rotor and the stator which, with rotation of the rotor, are caused to travel axially along the stator resulting in a smooth axial flow. Since the center of the screw describes a circle when rotating, drive is usually by means of a propeller shaft with universal joints which lie in the fluid flow see figure 3.43a.

Alternative methods of power transmission have been developed, see figure 3.43b. Some manufacturers have for example, a flexible connecting rod with rigid connections to the rotor and drive shafts instead of the previous universal joints. Others have developed new types of connections fitted with bellows and seals.

Increasing the length of the rotor and stator makes possible greater pressure increases. Pressure increase for a normal pump is between 0.6 and 1.0 MPa. Pressure increases of up to 3 MPa can be obtained by increasing the length.

PC pumps are available for volume flows from 0.1 to 300 m³/h,

The progressive cavity pump are used for practically all types of fluid from very fluent to very viscous. They can handle fluids containing abrasive contaminants and are relatively insensitive to solid particles. Larger pumps can allow the passage of particles of 30-40 mm diameter. Sometimes the fluid to be pumped is so viscous that special arrangements have to be made to feed the product to the pump suction inlet.

Figure 3.43b Different types of drive joint for PC pumps.

Progressive cavity pumps have good suction capacity 3-8 m but their extreme sensitivity to dry running limits their use.

Many different materials are used in the manufacture of the pump casings and rotors ranging from cast iron to titanium. The stator can be made from a wide variety of elastomers, for example natural rubber, nitrile rubber, neoprene and fluorocarbon. ln order to select the correct elastomer it is necessary to know the chemical properties of the fluid to be pumped and the temperature at which the pump is to operate. The choice of material is often a very difficult and complex matter whereby the advice of the pump manufacturer should always by sought.

A pump which is similar in appearance and has a similar range of use to the eccentric screw pump is the sliding vane screw pump, figure 3.43c. This type of pump also has a screw shaped stator but with a central rotating shaft fitted with a large number of sliding vanes, each vane being of short axial length. Pumping is performed by the sliding action of the vanes within the internal screw form of the stator. The stator is made of corrosion-resistant metal and the sliding vanes are usually plastic or metal. Sliding vane screw pumps should really be regarded as a vane pump with axial pumping action.

Figure 3.43c Sliding-vane screw pump, The illustration above (centre) shows the great number of vanes. The lower illustration shows the movement of the vanes in the shaft.