10.4 Pump control multi speed motor

Pump control multi speed motor

Regulation of pump performance using pump control multi speed motor require a pole changing induction motor. Special versions of induction motors with arrangements for changing the number of poles can be used for pump control. Pump speed is inversely proportional to the number of poles, see Chapter 6, section 6.1 Pump motor >>>

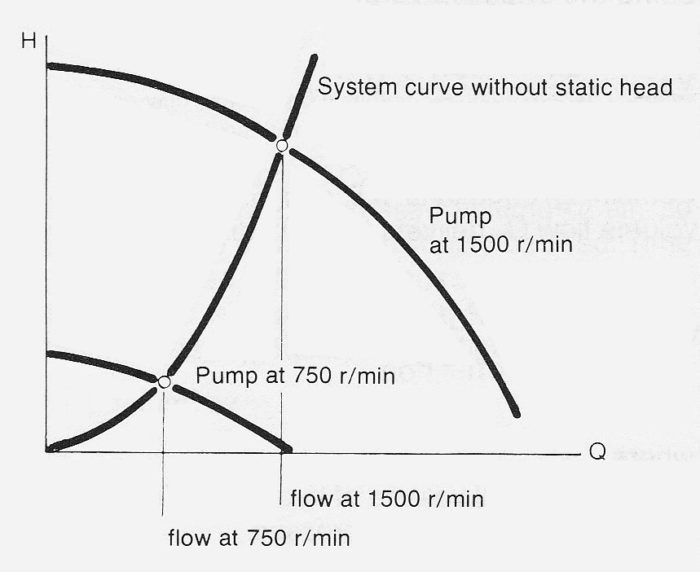

From the point of view of cost, a variation factor of two is the most favorable since this gives pump speeds of, say, 750/1500 or 1500/3000 r/min, although other steps are also possible. Pump performance changes in accordance with the affinity laws, see Chapter 3, Section 3.1.8 Pump similarity and affinity laws>>> , equations 3.18.

By using pole-changing motors (see section about Electric motor speed) stepped speed-regulation can be be achieved. For pump operation it is common to use two-speed motors whereby the combination of pole numbers determines the speed. The combination 2/4 gives speeds of 3000/1500 r/min, the combination 2/8 gives 3000/750 r/min. (somewhat less for induction motors). Lower efficiencies are normally expected at low speeds.

Pole-changing regulation is particularly favorable when the system curve has only pipe friction losses as in figure 10.4a, in circulation installations for example.

Since pole-changing regulation is a discontinous method of regulation, liquid storage is necessary. Dimensioning is carried out in the same way as for on-off control, Section 10.2 On off control for a pump. The permitted number of pole changes is usually between 1 and 15 times per hour.

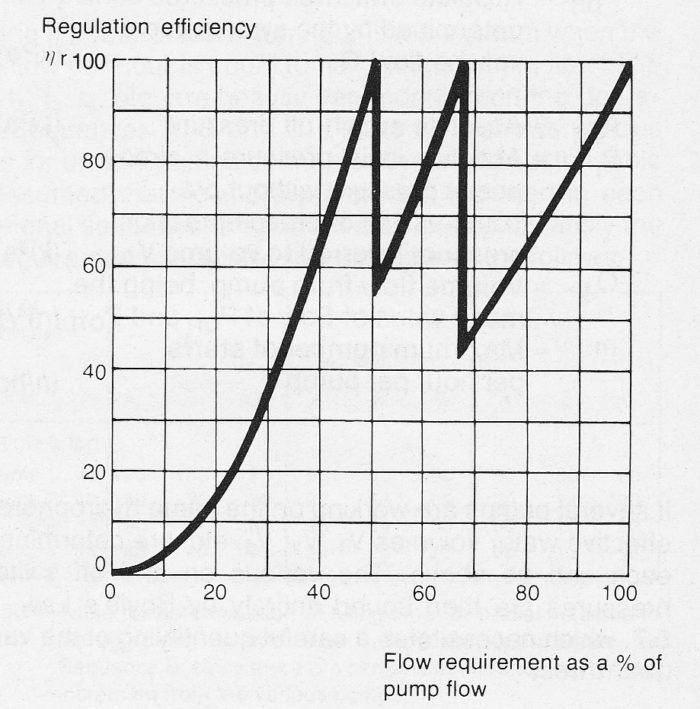

Pump and motor efficiencies are for practical purposes the same at the various speeds, which leads to good operational economy, see figure 10.4b. The cost of pole-changing motors is of the order of 20% to 40% higher than for normal, squirrel-cage induction motors. A limiting factor, to some degree, is the lower availability of this type of motor from manufacturers.

Figure 10.4a Example of change in performance due to pole-changing 750/1500 r/min. In this case the flow is halved by switching to 750 r.p.m.

Figure 10.4b Regulation efficiency for on-off control of a single centrifugal pump using pump control multi speed motor with 4, 6 and 8 poles. There is no static delivery head.