4.4 Pump materials for abrasive liquids

Pump materials for abrasive liquids

Liquids containing solid particles usually present considerable problems and demand pump materials for abrasive liquids. To some extent the problems can be eased by choosing a pump design suitable for abrasive liquids. Surfaces subject to wear can also be fitted with replaceable liners or designed with a good margin for wear. Examples of this are those pumps which are used for transporting abrasive solid materials such as ash, sand, macadam, etc. In these pumps, not only are the wear margins large but even the pump shaft systems are designed to cope with the imbalance resulting from such wear.

Two main groups of material are used for abrasive liquids, hard metals and various types of rubber cladding. Wherever rubber cladding can be used, with regard to particle size and liquid temperature, it is superior to the hard metal materials. Ceramics are also very good but, so far, plastics have not given very good results as pump materials for abrasive liquids.

Wear increases greatly with flow velocity for all qualities of material. It increases at least to the power of 3 with velocity, and cases are recorded of increases to the power of 7. This relationship infers that wear for a centrifugal pump with delivery head H increases in the proportion H3/2 to H7/2. Delivery head per pump stage is limited therefore and is a maximum of about 50 m for rubber-clad pumps and about 100 m for pumps made of wear-resistant metals.

Hard metallic pump materials for abrasive liquids

The following applies to hard materials, mainly steel with a high content of carbon and chromium:

- Material losses increase greatly when the hardness of the particles is greater than the material in the pump or liner.

- Material losses increase with the size and shape (sharp edged etc.) of the grain and in relation to the particle content.

- Wear-resistance is improved by increasing the hardness of the pump material, but this effect can only be significant if the pump material hardness figure exceeds about 300 Brinell.

- Combination of general hardness in the pump material with wear-resistance in individual elements in the pump material is a good thing. Examples of this are Ni-Hard, a martensitic chromium steel, wherein the wear-resistance is obtained from chromium carbide granules embedded in a hard matrix.

Rubber cladding

The wear-resistance of rubber cladding is due to the fact that solid particles more or less bounce on the rubber surface without actually damaging it. The following applies to rubber claddings:

- Soft rubber is better than hard rubber.

- Rubber gives favorable results if the particles strike the surface at right-angles, angle of incidence 90°, or if they move along the surface of the rubber. If the angle of incidence lies between 5° and 30° the results will be

much less favorable. - The thickness of rubber should be 2 or 3 times the size of the particle in order to exploit the bouncing effect.

- Sharp particles can cut the surface of the rubber to pieces.

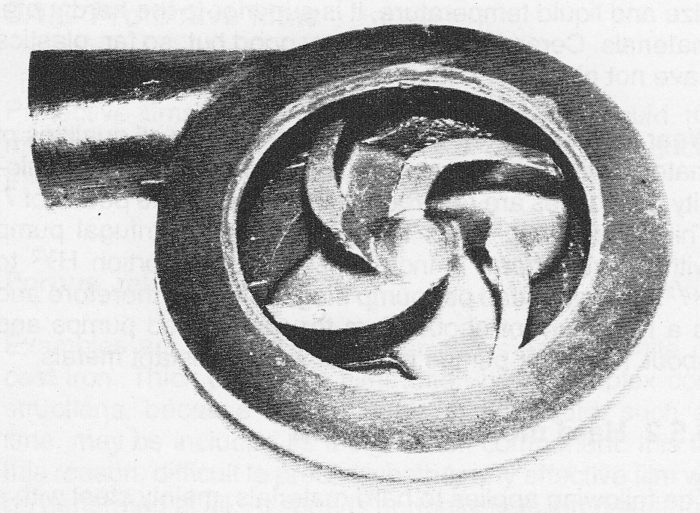

- Natural rubber is suitable for temperatures up to +70°C, whilst nitrile rubber can be more suitable when mineral oil contaminants are present although it is not so wear-resistant. Urethane rubber has become popular for parts of pumps used for abrasive pumping for temperatures up to about 50°C, see figure 4.4a. Urethane rubber has excellent wear properties and good resistance to oils, but polyester-based qualities are sensitive to hydrolysis. In this respect, polyester based urethane rubber (Adiprene) is better. Typically, urethane rubbers are considerably higher in price than natural rubber, however, this is compensated for with a simpler manufacturing process by forming in open moulds.

Figure 4.4a Pump impeller made of urethane coated steel and pump casing of solid urethane rubber.