3.10 Pump standard

Pump standard

Pump standard ´s are necessary since pumps as any other technology must be controlled by standards and regulations to ensure its safe and consequent application. Standards where initially applied to the dimensioning of machine elements. The scope and activities have been successively extended to cover all machine construction not only with regard to dimensioning but also to such parameters as performance, reliability and safety. Within the pump industry standardisation has developed in a similar fashion and today there are a considerable number of standards and regulations. There are also a number of standards which are in the process of preparation.

Pump standard issuing bodies

In principle, a standard can be issued by anyone. In order that the standard shall have practical meaning, however, the issuing organisation should be one that is recognised by both the manufacturer and the user of the object to be standardised. It is therefore normal practice for new standards to be developed by these three parties. The organisations which issue standards consist basically of the following categories:

- International standard organisations

- National standard organisations: often associated with central government.

- Trade societies and associations

- Corporations and large companies

- Classification societies

- Government authorities

The number of issuing authorities can therefore be very large and varying which often presents difficulties when developing new standards. Since there are many conflicting interests, especially when applied to international standards, the result is often a compromise with which none of the involved parties is completely satisfied. The advantages to be gained by the specification and general acceptance of standards and regulations however usually outweigh the disadvantages. The most important bodies for issuing standards within the pump industry are.

- ANSI – American National Standards Institute

- API – American Petroleum Institute

- ASME – The American Society of Mechanical Engineers

- ISO – International Organisation for Standardisation

ISO standards have now more or less replaced all old national standards developed by individual european countries (like BSI, DIN, IEC, VDI, VDMA etc.) and has become the most influential and important standardization body.

Standards which apply for marine use are issued by the classification societies such as Lloyds Register of Shipping, Norsk Veritas and the American Bureau of Shipping.

The most frequently used pump design standards

The concepts of reliability and operational life span have come more to the forefront in recent years as the demands for operational reliability and economy increase. This trend has been followed up by the organisations responsible for issuing standards and resulted in the development of instructions relating to pump design in order to fulfil these these requirements.

The advantages of standardised dimensions for individual components has long been recognized. The scope of standardization has been developed to cover all aspects of machine design and construction. Since size and performance are often related to each other, it has proved practical to develop standards which have regard to these two parameters.

Historically, ISO standards have had more impact in Europe and Asia, while ANSI standards are widely observed in the US and other parts of the Americas. However, there has been a degree of convergence as the two standards bodies borrow from each other. With the rise of globalization, ISO standards are increasingly influential.

An example of this is ISO 2858 which specifies the principle dimensions and nominal duty points of horizontal end suction centrifugal pumps for pressure rating PN 16 (16 bar). Water pumps of the same type but belonging to pressure class PN 10 are covered e.g. by the German standard DIN 24255. This standard covers pumps of approximately the same size as ISO 2858 but with reduced dimensions and higher port velocities. The ISO standard pump ISO 2858 or ISO 5199 is has not been accepted in the USA because of its metric dimensions. There is however an equivalent standard ANSI 73.1 which specifies dimensions and duty ratings in American units. In general, pumps manufactured to meet the ISO 5199 standard will meet or exceed ANSI B73.1 requirements in terms of performance, reliability, serviceability and longevity but can’t be used as direct substitutes for ANSI B73.1 machines without some adaptations to the mounting plates and motor couplings.

ISO Pump standards

- ISO 2858 includes horizontal, end suction single stage, centerline discharge design pumps. Maximum operating rating of 16 bar. Pump dimensions and nominal duty points are provided.

- Class I, ISO 9905:1994 comprises the most severe technical specifications for centrifugal pumps

- Class II, ISO 5199:2002 and

- Class III, ISO 9908:1993 the least severe requirements

Test | Guarantee | Grade | Grade 1 | Grade 2 | Grade 3 | |||

ΔtQ | 10% | 16% | 18% | |||||

ΔtH | 6% | 10% | 14% | |||||

Symbol | Acceptance grade | |||||||

1B | 1E | 1U | 2B | 2U | 3B | |||

Rate of flow | Mandatory | ΔtQ (%) | ±5 | ±5 | 0 to +10 | ±8 | 0 to +16 | ±9 |

Total head | Mandatory | ΔtH (%) | ±3 | ±3 | 0 to +6 | ±5 | 0 to +10 | ±7 |

Power* | Optional | ΔtP (%) | +4 | +4 | +10 | +8 | +16 | +9 |

Efficiency* | Δtƞ (%) | -3 | 0 | 0 | -5 | -5 | -7 | |

- reliability

- operating conditions

- environmental conditions.

If no acceptance grade is specified between the purchaser and the manufacturer, the standard reverts to the default test acceptance grade in table 3.102

American pump standards

The American National Standards Institute (ANSI) is a private, non-profit membership organization that was founded in 1918 as a cooperative venture by engineering organizations such as the IEEE, ASME and ASCE, and several US government departments. There are currently over 10,000 American National Standards (ANS) covering a wide range of products and processes.

American Pump standard ANSI B73.1 (sometimes referred to as ASME B73.1) was developed to address the needs of the chemical industry for single-stage end suction centrifugal pumps. The standard covers 27 pump sizes and specifies a number of key dimensions for each of these. Dimensions include overall height and length of the bare pump, nozzle and shaft diameters, the size, location and spacing of mounting bolts, replaceable wear rings etc. which means ANSI B73.1 pumps from different manufacturers can be readily substituted for one another.

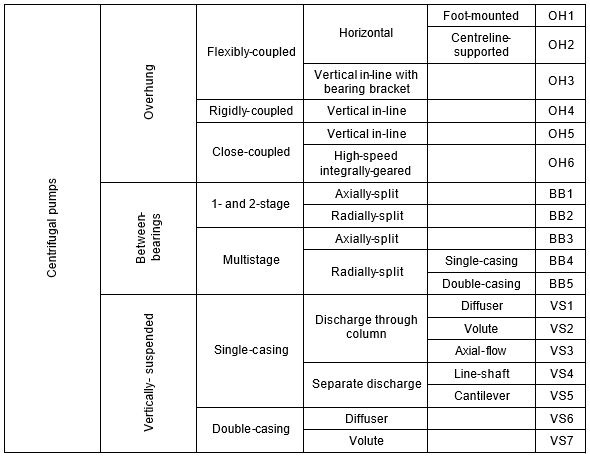

API Standard

The API (American Petroleum Institute) standard API610 concerning centrifugal pump reliability gives instructions and recommendations regarding the pump components which are associated with safety. Also dealt with are the factors which must be considered in a pump installation together with comments concerning the components such as shaft couplings and electric motors. The API standard applies primarily to the petroleum industry, but is also applicable in other areas. API 601 specifies requirements for centrifugal pumps, including pumps running in reverse as hydraulic power recovery turbines, for use in petroleum, petrochemical, and gas industry process services. It does not cover sealless pumps. This International Standard is applicable to overhung pumps, between bearings pumps, and vertically suspended pumps, all pumps are divided in categories according to the table 3.103 below.