3.65 Pump suction evacuation

Pump suction evacuation

Pump suction evacuation, i.e. starting a pump with the suction line empty will affect the pump differently depending on design. A centrifugal pump operating with atmospheric air instead of water produces a pressure increase which is about 1 000 times less. If the pump is placed above the level of the lower liquid surface and the suction line is filled with air the pump is thus incapable, when starting, of removing this air by itself. One refers to a centrifugal pump (or propeller pump) as being unable to evacuate its own suction line.

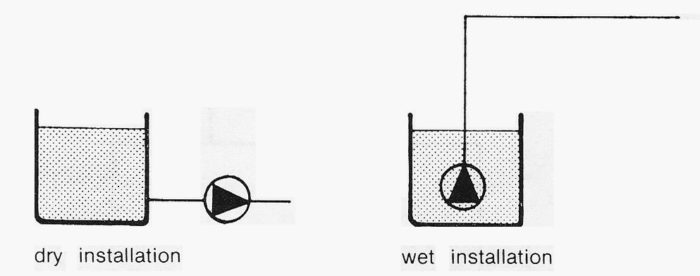

Before pumping can start it is therefore necessary to fill the pump with liquid. This can be arranged in a number of ways, figure 3.65a. Placing the pump below the level of the lower liquid surface eliminates the problem of evacuating and reduces the risk of cavitation. This supply head can be achieved for example, by immersing the pump or both the pump and the drive motor, so-called submersible pumps.

Figure 3.65a Pumps installed below the level of the lower liquid surface (supply head).

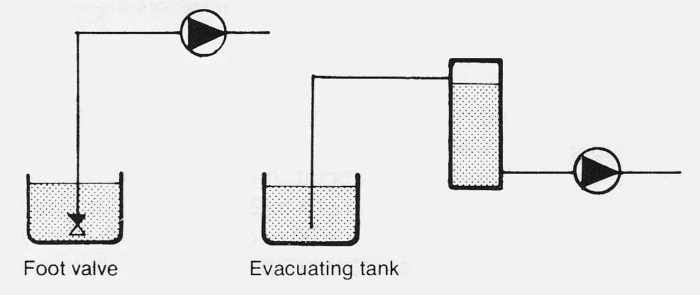

An alternative method of keeping the pump filled with liquid is shown in figure 3.65b. The non-return (foot) valve prevents liquid draining from the suction line when the pump is stopped. The foot valve is however, always subject to a small amount of leakage and also has the disadvantage that it causes large pressure losses within the suction line when pumping. The volume of the evacuating tank must be several times greater than the volume of the suction line. It is also necessary to check that cavitation does not occur in the suction line.

Figure 3.65b Foot valve and evacuating tank.

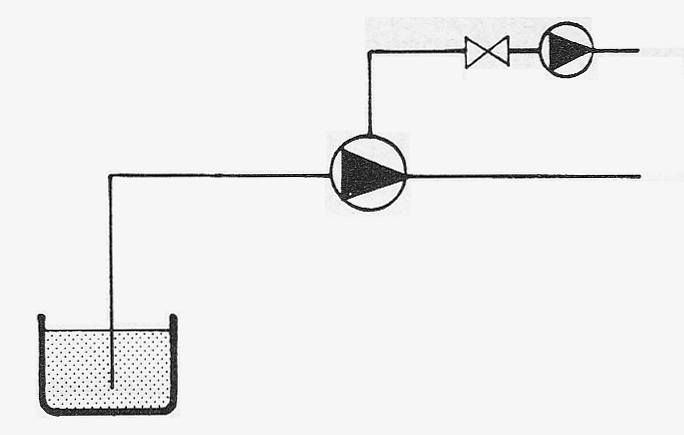

The air in the suction line and pump casing can be evacuated with the help of a smaller self-priming pump figure 3.65c. A large variety of pump types can be used as evacuating pumps. The most usual are liquid-ring pumps, side-channel pumps and jet pumps.

Figure 3.65c Evacuating pump

All displacement pumps are in principal self-evacuating providing that the inner seals are sufficiently effective and that dry running is acceptable during evacuation. It is therefore advisable to check with the manufacturer with regard to dry running, especially in the case of applications having long suction lines.

In the case of specially designed so-called self-priming centrifugal pumps the pump is built into a tank containing fluid. The evacuating process is then carried out automatically if the pump is filled with fluid.

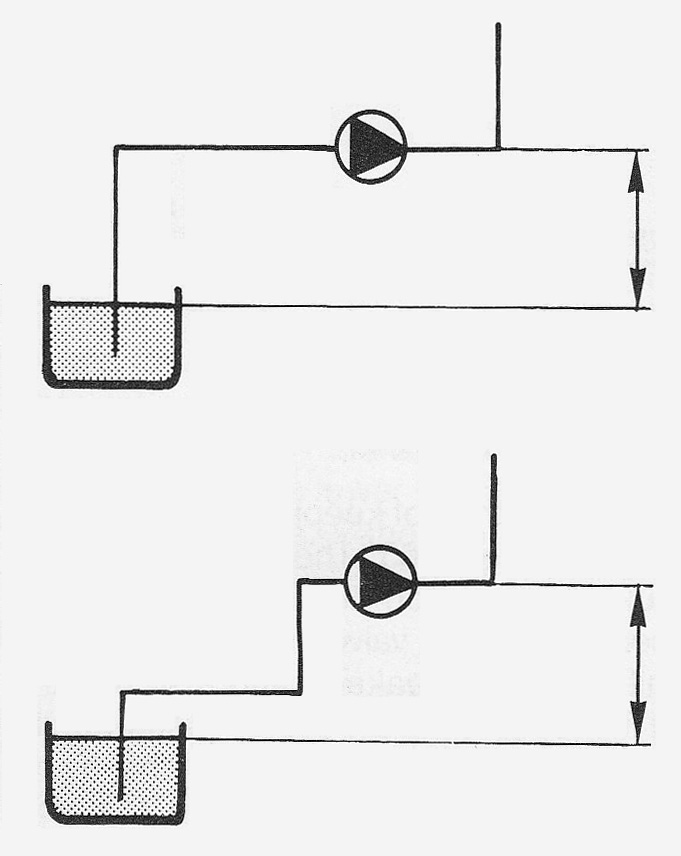

The routing and angle of inclination of the suction line has great influence upon the evacuation time. For a suction line routed as shown in the upper illustration of figure 3.65d, evacuation must be carried out at high vacuum for a large volume of pipeline before fluid begins to rise noticeably in the suction line. In the case of the suction line routed as shown in the lower illustration however, a relatively low vacuum will cause fluid to begin to rise in the suction pipe.

Figure 3.65d The routing of the suction line influences the evacuating process.

The suction line must be dimensioned with regard to both flow losses and evacuation time. Too large a suction line makes evacuation more difficult. A useful rule is to dimension for a delivery head loss of 1 to 2 m. If the volume of the suction line above the surface level of the lower fluid is very large, for example, for suction pipe lengths of several hundred metres, a foot valve must, without exception, be placed below the lower fluid surface.