9.3 Pump system curve viscous liquids

Pump system curve for viscous liquids

Pump system curve for viscous liquids and non-Newtonian liquids are different from systems pumping water. The pump and system curves have, in the previously illustrated figures, see Section 9.1 Pump System curve >>>, been representative of the relationships for centrifugal pumps and water-like liquids. For viscous and non-Newtonian liquids the curves have different shapes.

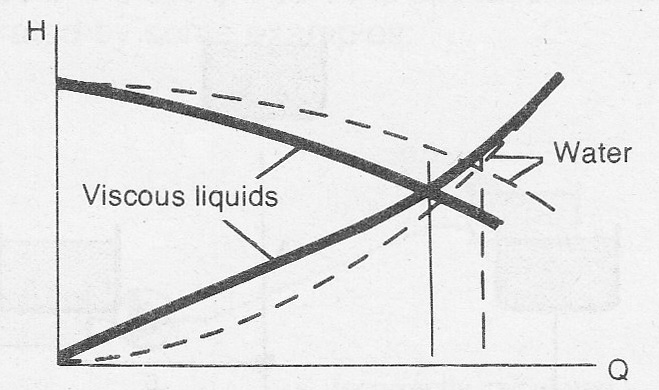

Figure 9.3a Pump and system curves for more viscous liquids compared with water.

For viscous liquids the laminar flow form is maintained at higher flow (flow velocities). The system curve thus becomes modified. The centrifugal pump Q-H curve falls off more quickly with increased volume flow for higher viscosity with a reduction in the flow passing through the pipe system.

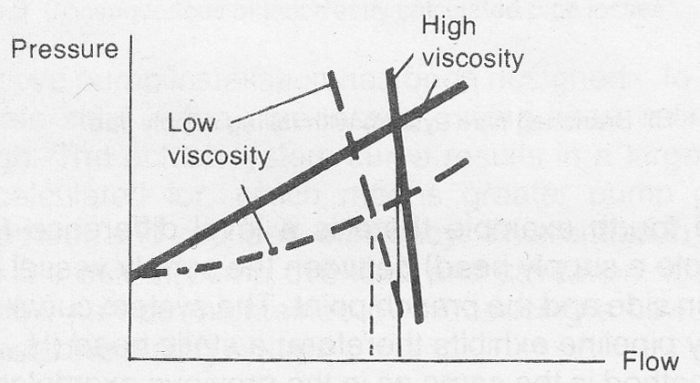

High viscosity liquids are normally pumped by positive displacement pumps, see Section 3.4 Positive displacement pump >>>. The high viscosity tends to reduce the internal leakage (slip). High causes large pipe losses. The system curve becomes completely linear if laminar flow is maintained at the actual flow condition. The high pipe losses tend to increase internal leakage. These factors combine to give us somewhat increased flow without a change in speed. The increased flow and increased pressure necessitates greater power requirements.

Figure 9.3b Positive displacement pump systems for different viscosities.

The pumping of chemical paper pulp is chosen here as an example of system curves for non-Newtonian liquids. The liquid characteristics of pulp suspensions is reflected in the shape of the system curve. The centrifugal Q-H curve also changes in relation to that for water.

Figure 9.3c Pump and system curves for water and paper pulp.

Since the pump’s operating point is always determined by the equilibrium between the pump and system, the shape of these curves is decisive from the point of view of pump installation performance. This applies also to the sensitivity to disturbances and part-load characteristics.