3 Pumps for liquids

Pumps for liquids

Pumps for liquids naturally comprises the most extensive chapter in the Pumphandbook. Four main categories of pumps are classified and treated. Each main category can be studied independently and contains the following sections; basics (theory), performance curves, design classification and a description of different design types. The classification into categories recurs in both the list of contents as well as in those sections dealing with classification by design. This classification by categories is applied consistently throughout the rest of the information in the book. The description of up to fifty different types of pumps is relatively brief, but should, however, be of benefit both to the layman as well as to the specialist in this area. The sections about Suction capacity and Standards are intended to be applicable to all sorts of pumps, even if centrifugal pumps have tended to dominate due to their wide range of application. Suction capacity comprises not only the classic concepts of cavitation, suction lift and NPSH, but also the evacuation of suction lines and the effect of gas (air) dissolved or entrained in liquid.

Pumps for liquids are used everywhere there is a need for fluid transportation or circulation. Sometimes it is clean liquid which is pumped, sometimes the liquid is used as a medium for

carrying heat or solid suspended material etc. Due to widely varying operational requirements there are a large number of different pump designs on the market. A classification into four main categories has been made in an attempt to provide a clear picture of the types of pumps for liquids in use today.

- Rotodynamic pumps hereinafter mainly called Centrifugal pumps

- Liquid ring pumps

- Positive displacement pumps

- Other pumps

Centrifugal pumps

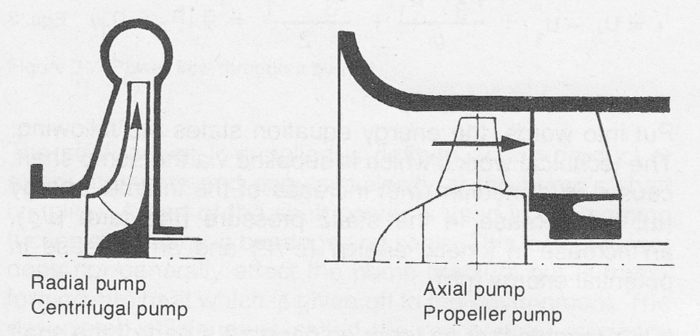

The design of centrifugal pumps is characterized by one or more impellers equipped with vanes which rotate in a pump casing. The forces generated between vanes and liquid when the liquid flows around the vanes are utilized in the conversion of energy. The centrifugal pumps are named radial pumps or axial pumps depending on the main direction in which the fluid flows through the impellers. Alternatively, the terms centrifugal pumps for radial pumps and propeller pumps for axial pumps are used. Intermediate forms between purely radial and purely axial pumps are also found and as such, are termed mixed flow pumps or in certain cases diagonal pumps. Figure 3.1 shows the most usual and most important of the pumps in the rotodynamic pump category.

Figure 3.1 Examples of Rotodynamic Pumps

Liquid ring pumps

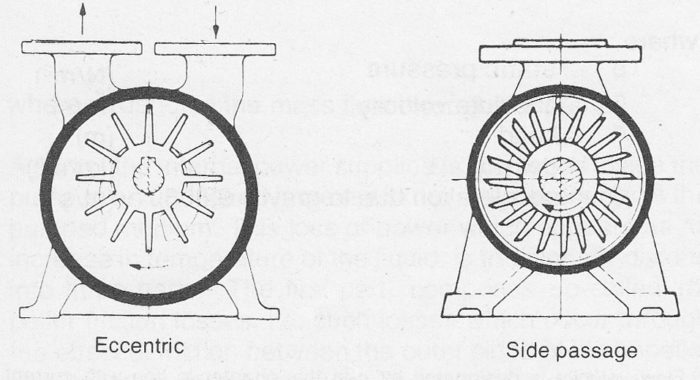

Certain aspects of liquid ring pumps are related to positive displacement pumps. A liquid ring is formed along the inner wall of the pump casing when the placed impeller rotates. During a revolution of the impeller the partial volumes in the gaps between the vanes inside the liquid ring are first increased (inlet) and then decreased (outlet). A variant of liquid ring pumps has the impeller placed centrally and brings about the varying pallial volumes trapped during the revolution by allowing the liquid ring to partially wander out into channels in the side walls of the pump casing. The depth of these side channels varies during the revolution. Liquid ring pumps are self-priming.

Figure 3.2 Examples of liquid ring pumps

Positive displacement pumps

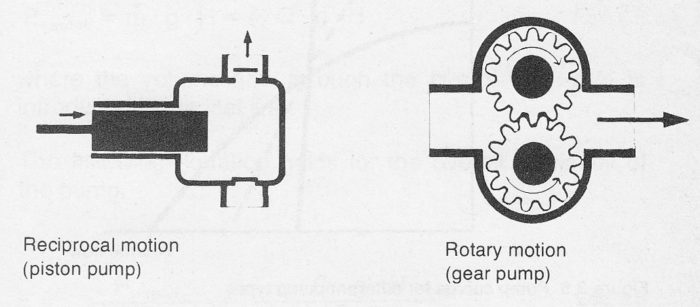

Positive displacement pumps operate with closed-in liquid volumes which are forced forward in the direction of pumping and expelled into the pump outlet. The oldest and perhaps the most typical positive displacement pump is the piston pump. A certain volume of liquid is pressed out of the cylinder for each stroke of the piston. The piston pump belongs to the sub category among the positive displacement pumps which operate by means of a reciprocating motion. The other sub category is comprised by the rotating positive displacement pumps.

These include, for example, gear pumps where the liquid is transported in gaps between the gear teeth and where the difference in pressure is maintained by means of, among others, the seal afforded by the contact surface of the meshing gears. Other examples of rotating displacement pumps are screw pumps, vane pumps, hose pumps, etc.

Figure 3.3 Examples Of positive displacement pumps

Other pumps

Jet pumps and pitot tube pumps can be cited as examples of the main category termed “Other pumps”. The static pressure in the nozzle of the jet pump falls when the speed of the motive (driving) medium increases. The pumped medium is sucked in and mixed with the motive medium. The overall speed of the fluid flow is reduced and the static pressure is

increased in the jet pump venturi (diffuser). Jet pumps are used, among others, as vacuum pumps and are self priming.

Figure 3.4 Pitot tube pump and Jet pump are examples of pumps from the main category “other pumps”

The rotating casing of the pitot tube pumps accelerates the incoming liquid to a high speed. A high static pressure is present at the stationary mouth of the pitot tube and is brought about both by the effect of centrifugal forces and by the braking effect on the liquid prior to the pitot tube. Pressure increases of up to approx. 10 MPa can be achieved utilizing this methode.