3.5.4 Rigid screw pump

Rigid screw pump

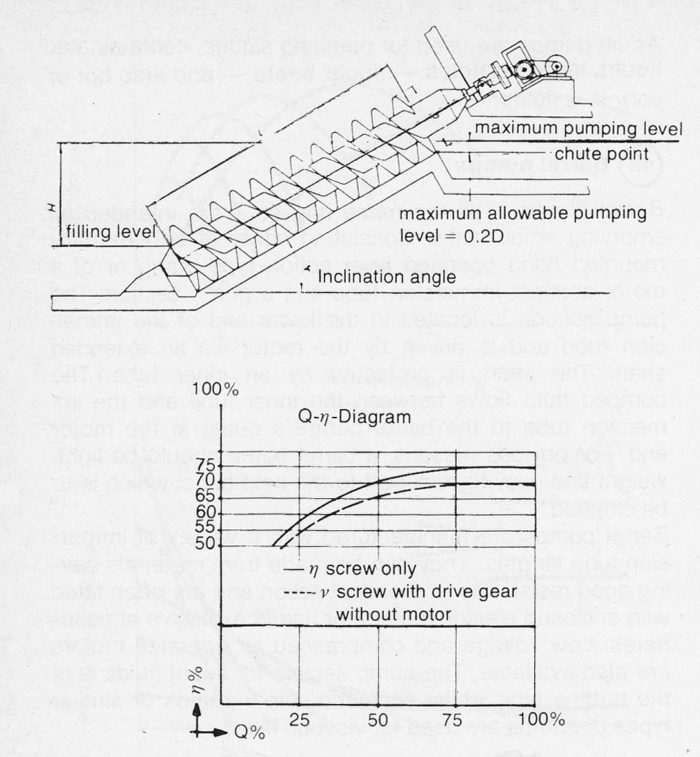

The rigid screw pump is a development of the Archimedean screw, which is the oldest known type of rotating pump. The rotor is in the form of a helical blade. The number of blades varying from one to three. The rotor usually rotates in an open channel (sump) having a circular cross-section, enclosing about three-quarters of the rotor periphery. The rigid screw shaft is usually inclined at an angle of 30° to the horizontal, the length of the screw being approximately twice the lift obtained. The lift heads are moderate, rarely in excess of 10 m. Increased nominal flow is obtained by increasing the rotor diameter and reducing speed. Speeds range between 20-80 r/min.

Delivery heads are virtually independent of flow up to a maximum flow, maximum capacity loss factor (filling co-efficient). The efficiency curve is flat. As shown in figure 3.54a the efficiency is only reduced by about 5% from full load to 50% flow. Figure 3.54a shows example of rigid screw pumps construction principle and efficiency.

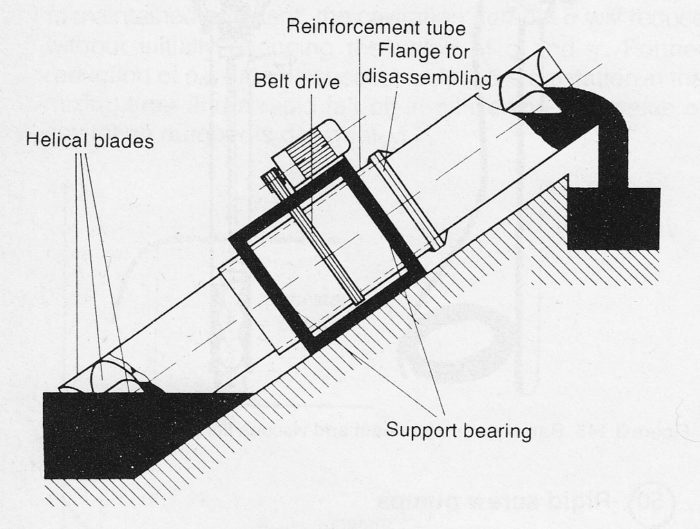

There are special types of rigid screw pumps like that shown in figure 3.54b, where the channel is totally enclosed and rotates with the screw. Provided that the drive and shaft bearings are completely isolated from the fluid it is thus possible to transport a large variety of fluids.

Rigid screw pumps are used for transporting liquids containing large solid contaminants untreated sewage for example. Low delivery heads and large flows are ideal for rigid screw pumps. As a sewage pump the rigid screw pump is self-regulating according to the supply flow. When the level in the pump sinks then the capacity loss factor (filling coefficient) automatically reduces causing the pump flow to decrease.

The advantages of the rigid screw pump are as follows:

- High efficiency

- Flat efficiency curve

- Self-regulating for varying supply flows

- Not sensitive to contaminants

The rigid screw pump can only be used for large installations with small delivery heads.