- 1 Installation and maintenance

- 2 Pump selection fundamentals

- 3 Pumps for liquids

- 3.1 Centrifugal Pumps

- 3.2 Centrifugal pump type

- 3.2.1 Water pump

- 3.2.2 Domestic heating and sanitation pumps

- 3.2.3 Automatic water pumps

- 3.2.4 Irrigation pumps

- 3.2.5 Machine tool coolant pumps

- 3.2.6 Submersible deep well pumps

- 3.2.7 Deep well pumps with ejector

- 3.2.8 Groundwater pumps and sump pumps

- 3.2.9 Marine pumps

- 3.2.10 Multi stage pump

- 3.2.11 Sealless pumps

- 3.2.12 Magnetic driven pumps

- 3.2.13 Canned pumps

- 3.2.14 Slurry pumps

- 3.2.15 Food processing pumps

- 3.2.16 Sewage pump

- 3.2.17 Double suction pump

- 3.2.18 Axial pump

- 3.2.19 Washing pumps

- 3.2.20 Pulp pumps

- 3.2.21 Plastic pumps

- 3.2.22 Non clogging pump

- 3.2.23 Propeller pump

- 3.3 Positive displacement pump theory

- 3.4 Positive displacement pump

- 3.4.1 Gear pump

- 3.4.2 Screw pump

- 3.4.3 Progressive cavity pump

- 3.4.4 Lobe rotor pump

- 3.4.5 Vane pump

- 3.4.6 Peristaltic pump

- 3.4.7 Piston pump

- 3.4.8 Diaphragm pump

- 3.4.9 Metering pump

- 3.4.10 Eccentric screw pump

- 3.4.11 Rotating piston pump

- 3.4.12 Impeller pump

- 3.4.13 Hose pump

- 3.4.14 Plunger pump

- 3.4.15 Membrane pump

- 3.4.16 Dosing pump

- 3.5 Other pumps

- 3.6 Pump cavitation

- 3.7 Pump application calculation example

- 3.10 Pump standard

- 4 Materials for pumps

- 5 Pump seal

- 6 Pump drives

- 7 Properties of liquids

- 7.1 Water properties

- 7.2 Sea water properties

- 7.3 Pumping oil

- 7.4 Pumping suspensions

- 7.5 Properties of sewage for pumping

- 7.6 Properties of sludge pumping

- 7.7 Properties of paper pulp pumping

- 7.8 Liquid table

- 7.8.1 Liquid property table

- 7.8.2 Viscosity of thixotropic alkydes

- 7.8.3 Viscosity diagram for black liquor, sulphate liquor

- 7.8.4 Vapour pressure diagram

- 7.8.5 Density for liquids at various temperatures

- 7.8.6 Density against concentration for bases

- 7.8.7 Density against concentration of acids

- 7.8.8 Density against concentration of salts

- 7.8.9 Density concentration for various salts cont

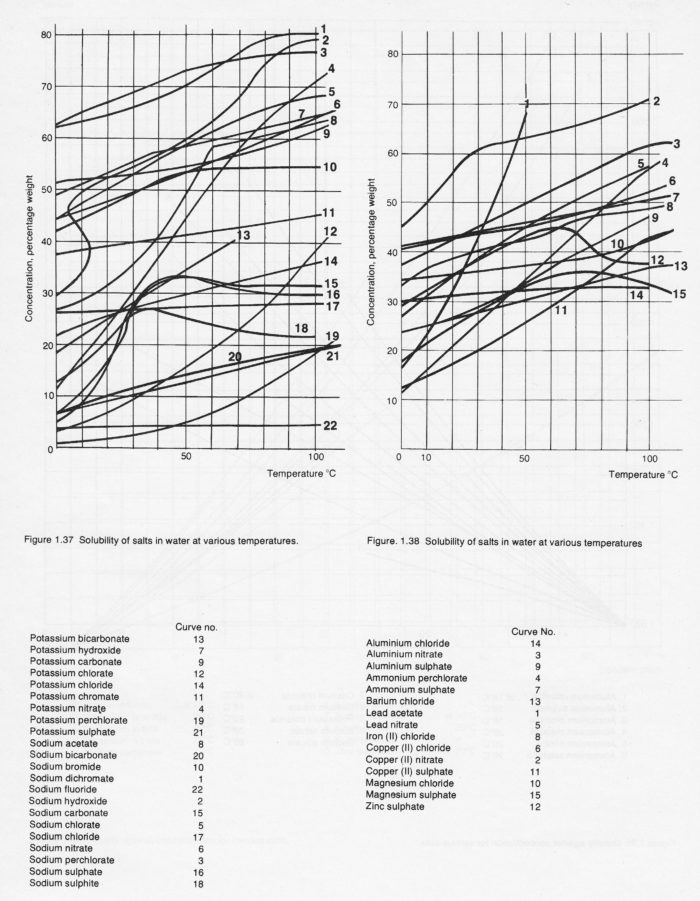

- 7.8.10 Solubility of salts in water

- 8 Liquid flow

- 8.1 Continuity equation

- 8.2 Bernoulli equation

- 8.3 Momentum equation

- 8.4 Energy equation

- 8.5 Pipe flow losses

- 8.6 Head loss

- 8.7 Hydraulic diameter

- 8.8 Total head loss in pipe system

- 8.9 Head loss pumping suspensions

- 8.10 Head loss calculation paper pulp

- 8.12 Pressure loss nomogram and diagram

- 8.13 Head loss in pipe nomogram and diagram

- 8.13a Flow velocity in cylindrical pipes

- 8.13b Relation between loss coefficient and loss of head

- 8.13c Head loss in pipe diagram

- 8.13d Frictional loss diagram for water

- 8.13e Frictional pipe head loss for water

- 8.13f Head loss in pipe for water diagram

- 8.13g Frictional pipe loss for water

- 8.13h Pressure loss in pipe diagram

- 9 Pump system

- 9.1 Pump system curve

- 9.2 Branched pipe system

- 9.3 Pump system curve viscous liquids

- 9.4 Valve pressure drop

- 9.5 Series pump operation

- 9.6 Parallel pump operation

- 9.7 Booster pump

- 9.8 Pressure maintenance pump

- 9.9 Pump specification

- 9.10 Water hammer

- 9.11 Water hammer protection

- 9.12 Pump behavior power outage

- 10 Pump flow