6.3 Starter apparatus and protection for pump motor

Starter apparatus and protection equipment for pump motor

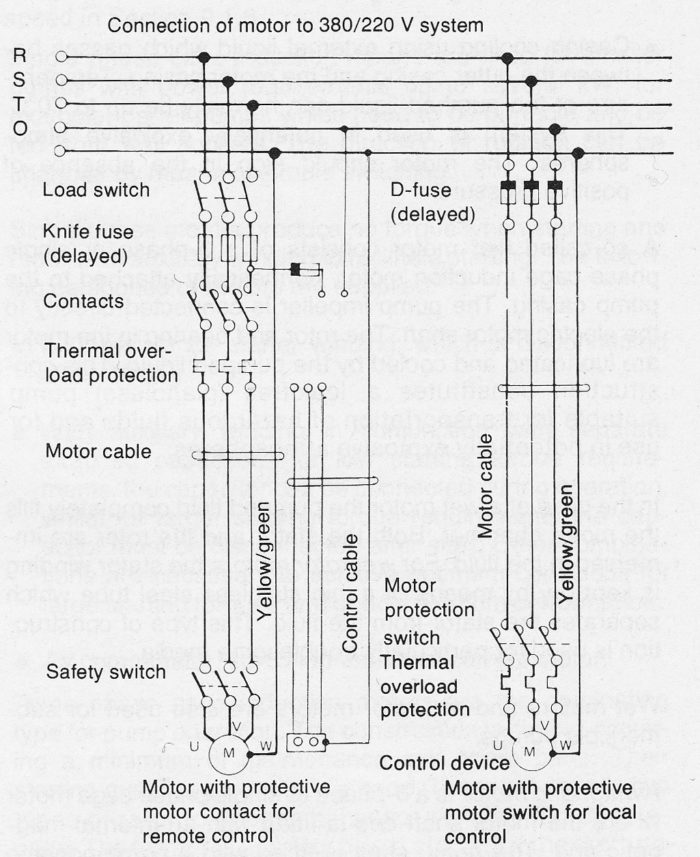

The simplest starter apparatus and protection for a pump motor is a hand operated switch. Electro-magnetic controlled connecting apparatus is used in more sophisticated processes. These can be remote controlled. Various types are used, Starters and controllers for electric motors must, according to relevant regulations be combined with protection devices against excess current so as to prevent dangerous overloading of the motor. This protection can consist either of overload protection or short-circuit protective devices (see below) or a combination of both.

Direct-on-line starters for cage induction motors are usually equipped with a contactor and overload device.

Forward and reverse switches are used for electric motors which run in both direction of rotation.

Star-delta starters (Y/D-starters) or transformer starters are used when it is necessary to limit the starting current. The latter produces a reduction in voltage during starting which thus reduces the starting current. Slip-ring motors utilize a stepped starter resistance (rheostat).

Overload protection

The overload protection will prevent damage to the motor which can be caused by high temperature because of overloading or too high current consumption. Overload protection normally consists of a thermal motor protection device (bi-metallic) which reflects the thermal behavior in the motor. The thermal protection device switches off the current in all the phases before the temperature exceeds a value which cause damage to the insulation. Over-load protection is usually set at the motor rated current or slightly under.

Short-circuit protective devices

The purpose of the short-circuit protective device is to quickly disconnect the motor from the grid in the event of a short-circuit or earthing fault. For moderate short-circuit currents fusible cut-outs are suitable, so-called plug fuses or Diazed type. These can be used for currents up to 60 A. For larger currents, high power knife type fuses are used.

Fuses are available as rapid or delayed action types. Motors use delayed action fuses to avoid unnecessary cut-out when starting.

Temperature sensors

For unfavorable conditions the normal motor protection devices may need to be complemented with special temperature sensors (thermistors). These are built into the stator winding. Submersible motors and wet rotor motors are usually fitted with such termistors.

Safety switch

The safety switch should always be placed as near to the motor as possible and marked with a sign Safety switch and equipped with an open position locking device. For high voltage motors the safety switch is not located at the motor but is placed in the control room.

Ammeter

The ammeter is used for measuring the motor’s operational current. Even for smaller motors an ammeter should be installed so as to facilitate monitoring of the motor in operation. An ammeter is often included in the motor starter apparatus.

Figure 6.3a Example of electric pump motor connection to AC 380/220 V system current grid with starter apparatus and protection devices.